Material Density Guide

Material bulk density is one of the most important factors in designing the correct equipment for your needs. While the best way to be certain of your material’s bulk density is to send us a sample or calculate it yourself using the guidelines below, we do offer our Bulk Density Guide as a starting point.

View Our Material Density GuideEquipment Configurators

Hapman’s interactive design tools give you the power to design your own equipment, view 3D models and download the CAD and BIM formats you need.

Start Designing Your EquipmentOur case studies and Application Expertise offer valuable insight into equipment solutions, new technology and the challenges facing today’s material handling applications.

Featured Application Expertise

See all Application ExpertiseVolumetric Vs. Gravimetric Feeder Operation

How Much Control Is Achieved with Volumetric vs. Gravimetric Material Feeding? Whether you work in the manufacturing or production industry,…

Unload, Convey, Fill, Repeat

Maggie Beauchamp, a Hapman sales rep from Gull Material Handling Company, contacted Hapman product specialist, Stephanie Avery, regarding a customer…

Conveying Dried Biosolids

Hapman partners with several major Wastewater Treatment facility developers meeting critical requirements around dosing treatment materials and sludge handling. Hapman…

Calculating Bulk Density

Bulk density is an important calculation if you want your equipment sized correctly. Here are a few simple steps to…

Featured Case Studies

See all Case StudiesHelix® Flexible Screw Conveyor Feeds Innovative Form-Fill-Seal Packaging Solution

Based in Grand Rapids, Michigan, IMS Group USA offers bulk solids packaging solutions for the food, pharmaceutical, resin, chemical and…

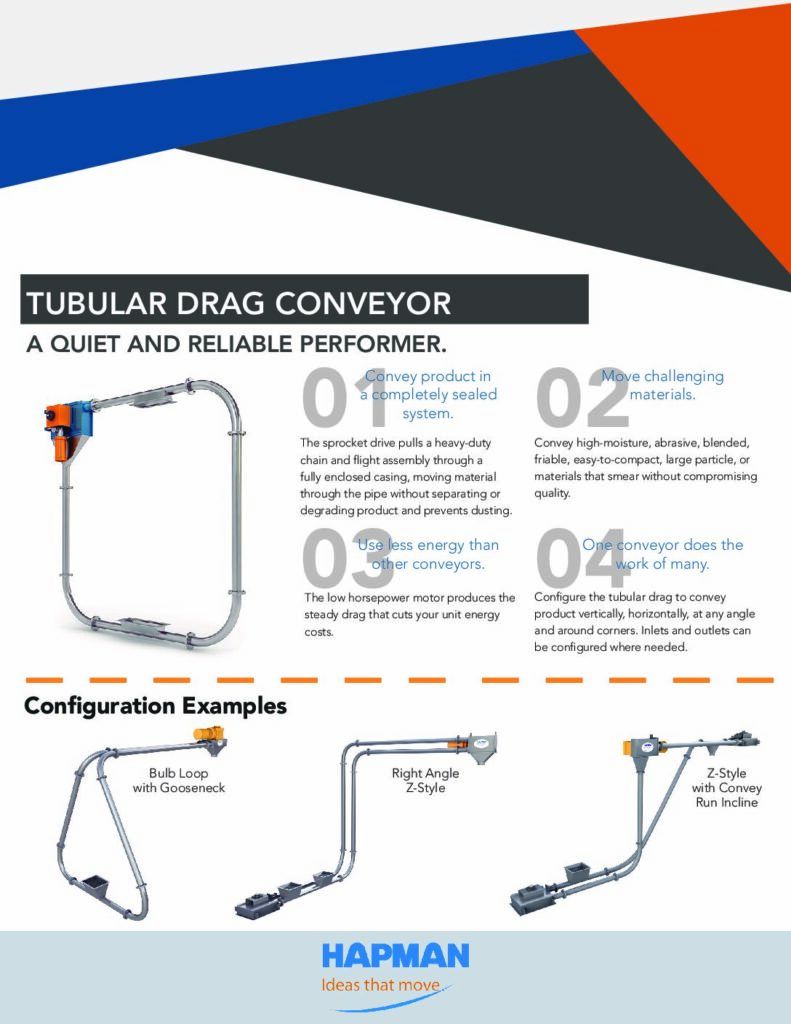

Issues of Unloading Ammonium Nitrate Prill are Eliminated with Tubular Drag Conveyor System

“Hapman and their local representative worked very hard to ensure the successful completion of our client’s project,” stated O’Connor. “Their…

Easy-to-Clean. Cost Effective. Trouble-free Operation. Helix® is the Top Choice for Specialty Dry Bulk Food Company

Planning for expansion is a critical step in a company’s growth plans. Especially when evaluating process improvements and new equipment…

Bulk Bag Filler – Plastics Manufacturer Uses Bulk Bag Filler FIBC System

CHALLENGE A plastics manufacturer needed a bulk bag filler that could be adjusted to fill a variety of large bag…

Featured Insights

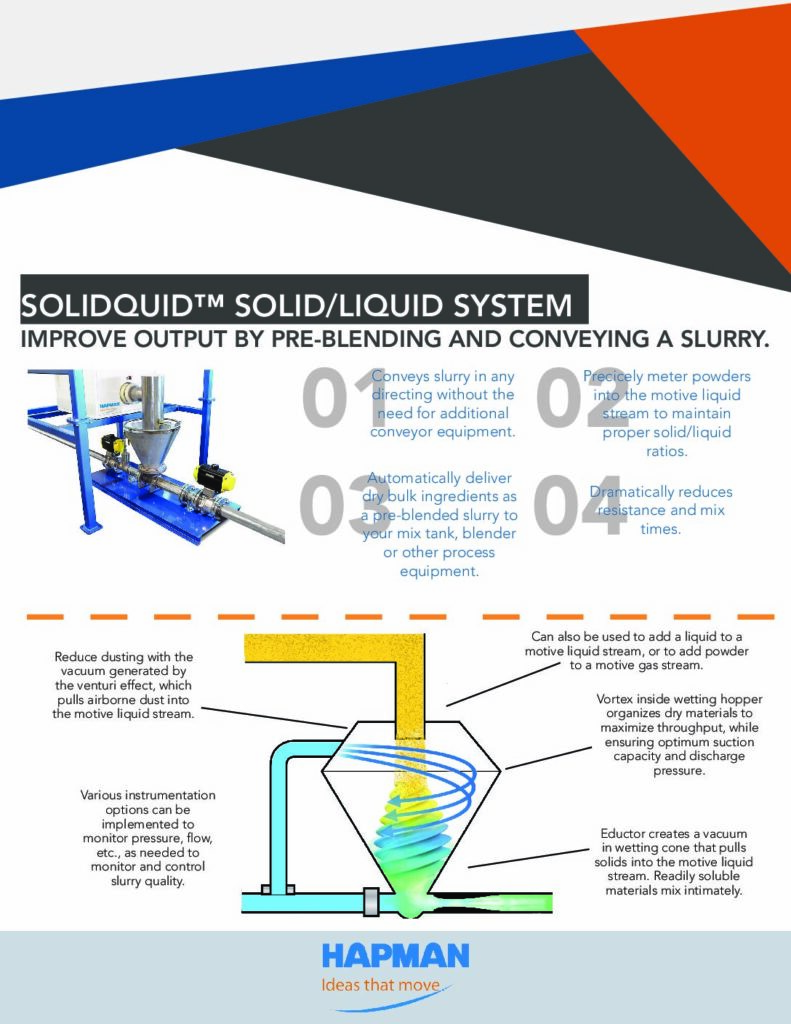

See all InsightsEductors: What Are They and How Do They Work?

When creating a fluid or pneumatic conveyor system, eductors can be a good options in place of fans, blowers, and pumps.…

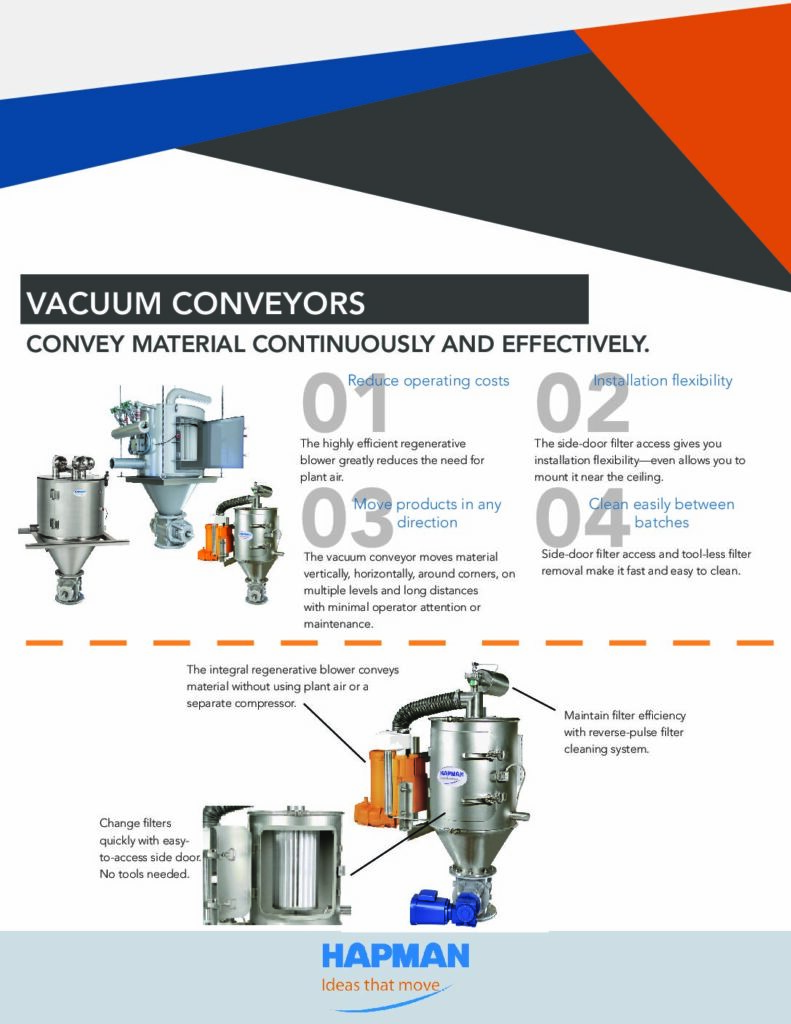

Using Material Handling Automation to Improve Efficiency

Take a closer look at three main types of material handling automation and the Hapman difference in designing and integrating…

Challenges in Conveying Bulk Materials

When plants deal with bulk material well, all of their operations become easier. But challenges in bulk material handling lead…

3 Reasons Why a “Regular” Flexible Screw Conveyor Might Not Work for You

Manufacturers commonly use flexible screw conveyors because of their low cost, reliability, straightforward operation and simple construction. This equipment is not complicated,…