Versatile, Effective Material Movement

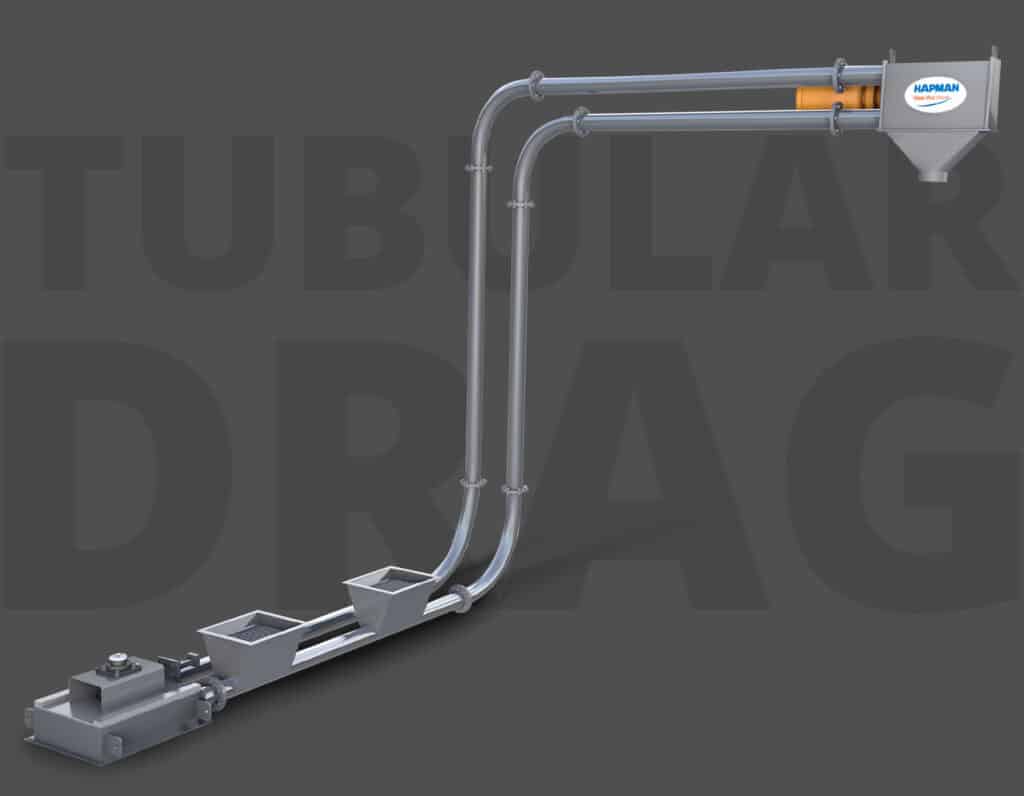

Hapman conveyors offer the simplest, easiest operation and maintenance on the market. Flexible screw, vacuum, and tubular drag designs give you the ultimate in versatility to move almost any bulk material. They’re designed and built to provide a long service life in your operations.