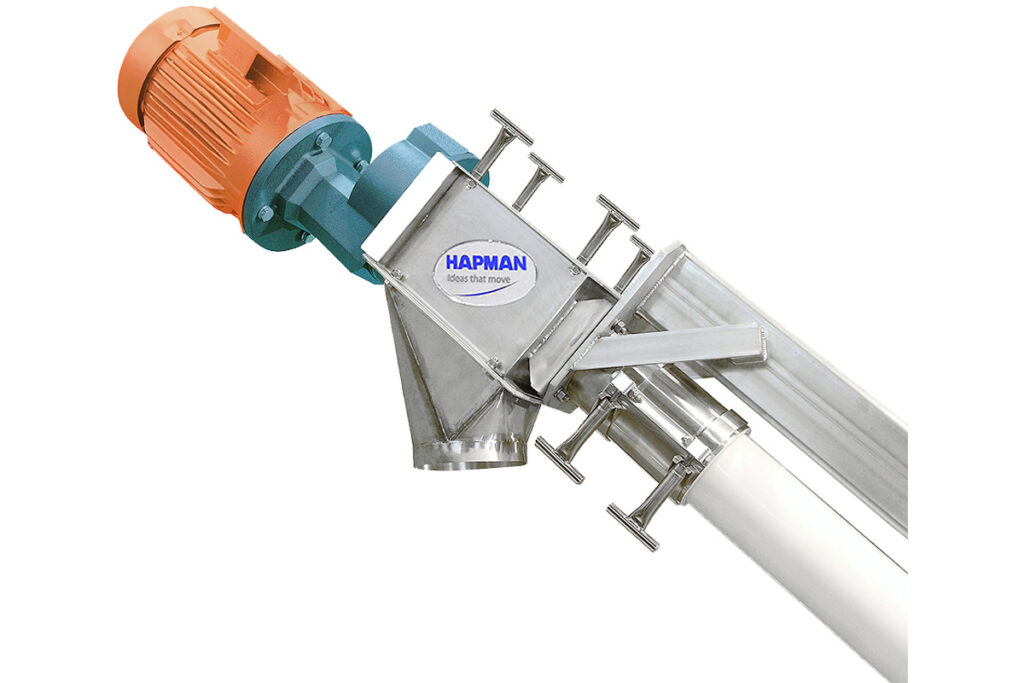

Helix® Flexible Screw Conveyor

- Conveniently convey bulk material up to 25 cfm.

- Available in 2.5” to 8” diameter sizes.

- Quick-Ship (ship in 48 hours).

The Helix® Flexible Screw Conveyor is a versatile and reliable solution for all your material handling needs. Whether you need to transport powders, granules, or other bulk materials, the Helix® has got you covered. And with its easy disassembly and customizable options, it’s the perfect choice for industries such as food processing, pharmaceuticals, chemicals, and more.

Our helicoid screw rotates within a fixed tube, ensuring efficient material conveyance from point A to B. With its exclusive T-handles couplings, you can disassemble this conveyor in just minutes for easy cleaning and minimal downtime. Plus, with a multitude of customizations available, the Helix® can adapt perfectly to your unique requirements.

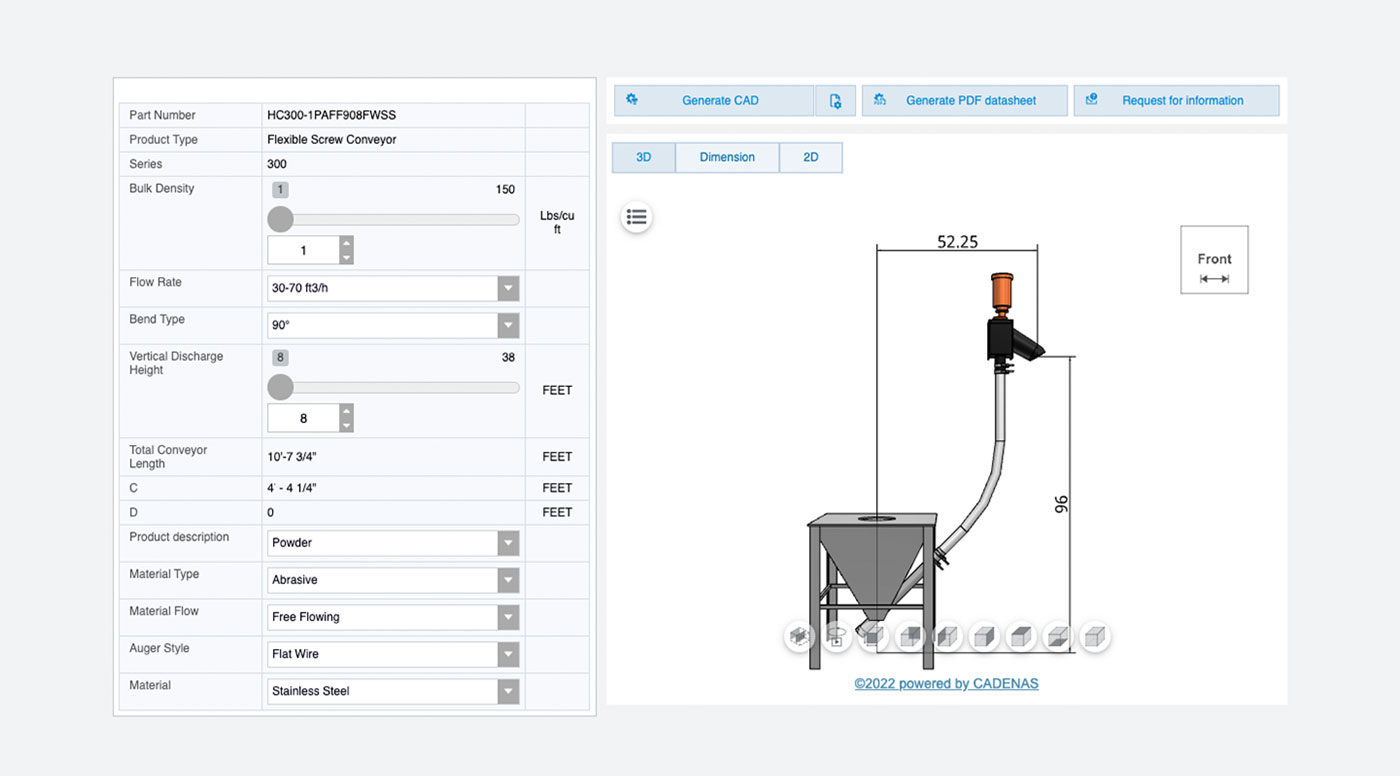

Use the Hapman Configurator for on-demand access to design custom solutions for your application and immediately obtain reference models and drawings.

Quick-Ship Ships in 2 Days or Less!

We designed our Hapman Helix Flexible Screw Conveyors to provide customers with an economical conveying method that can be used for most types of dry material handling applications.

Our Performantee is a 100% operational guarantee that you will be fully satisfied with the performance of our equipment, and that it will achieve the specific results for which it was designed and manufactured. If not, we will revise or repair it to deliver the results we promised.

Have Technical Questions About Our Helix Flexible Screw Conveyors?