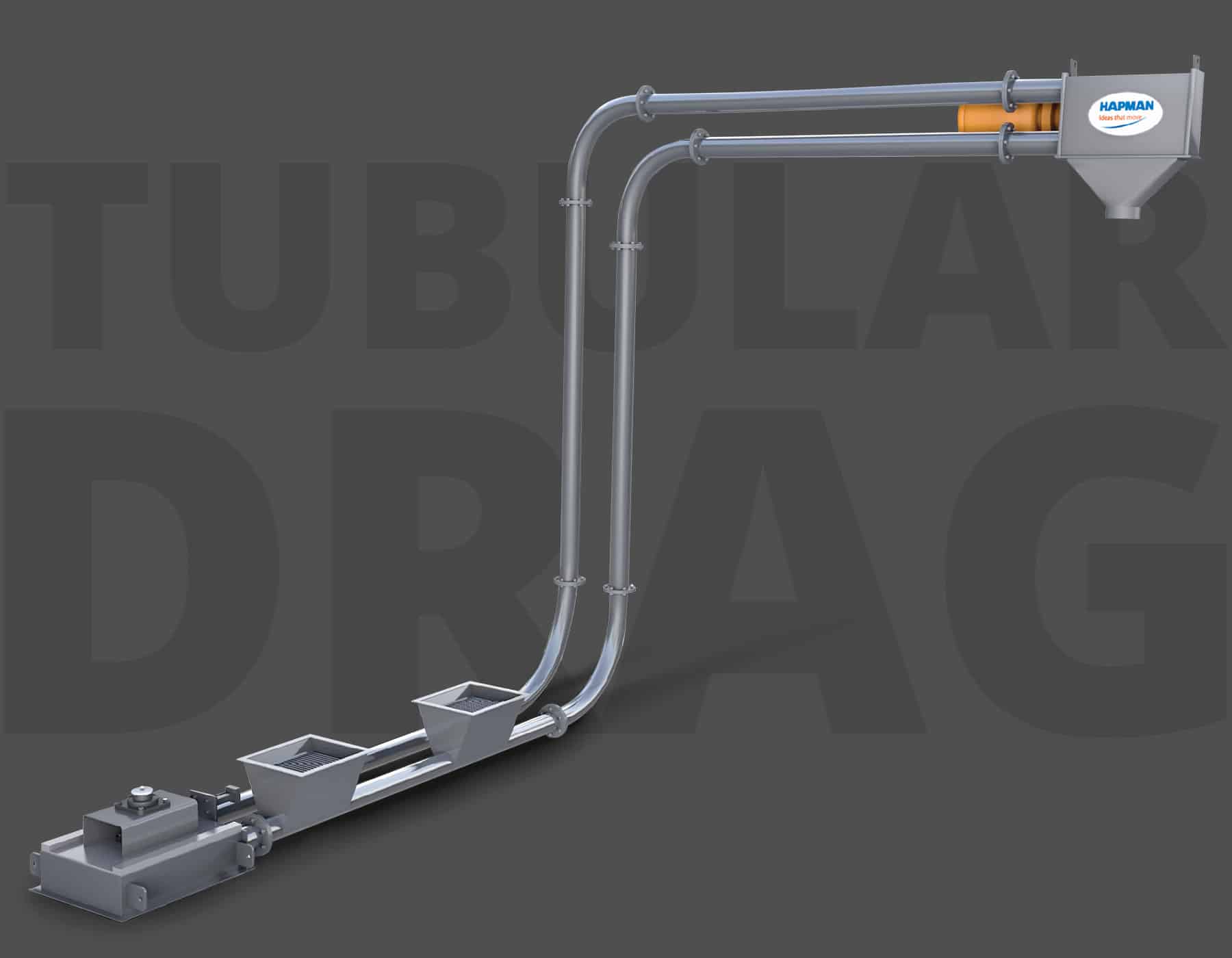

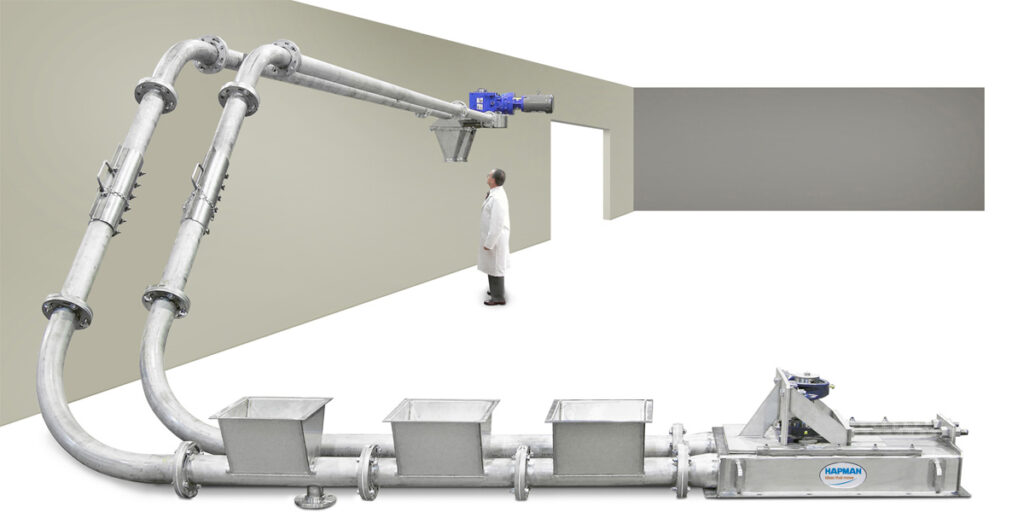

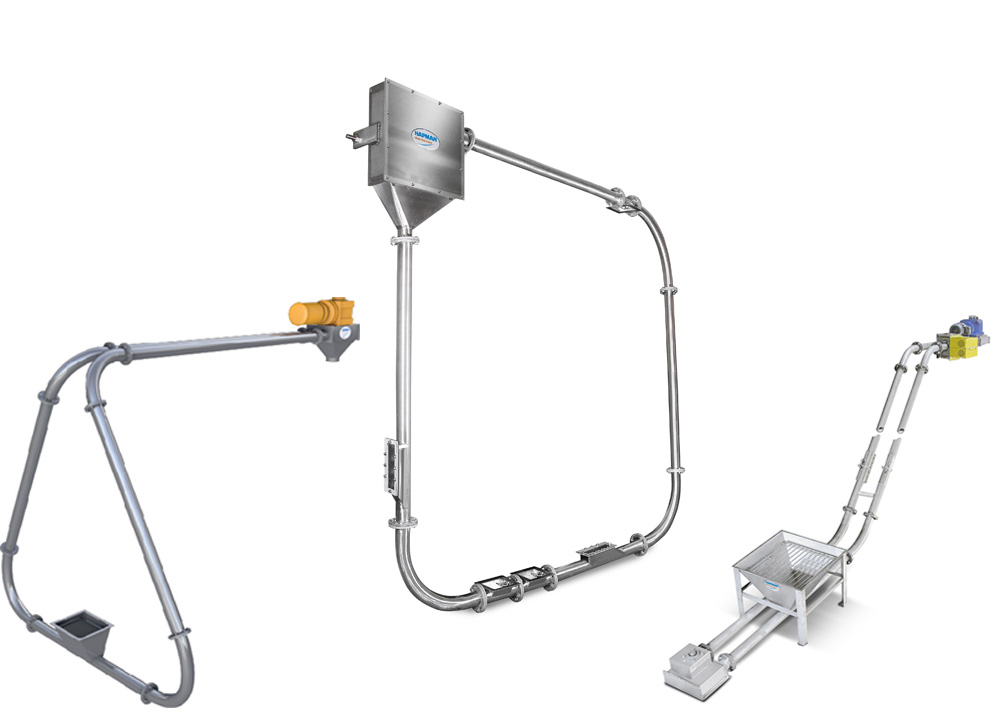

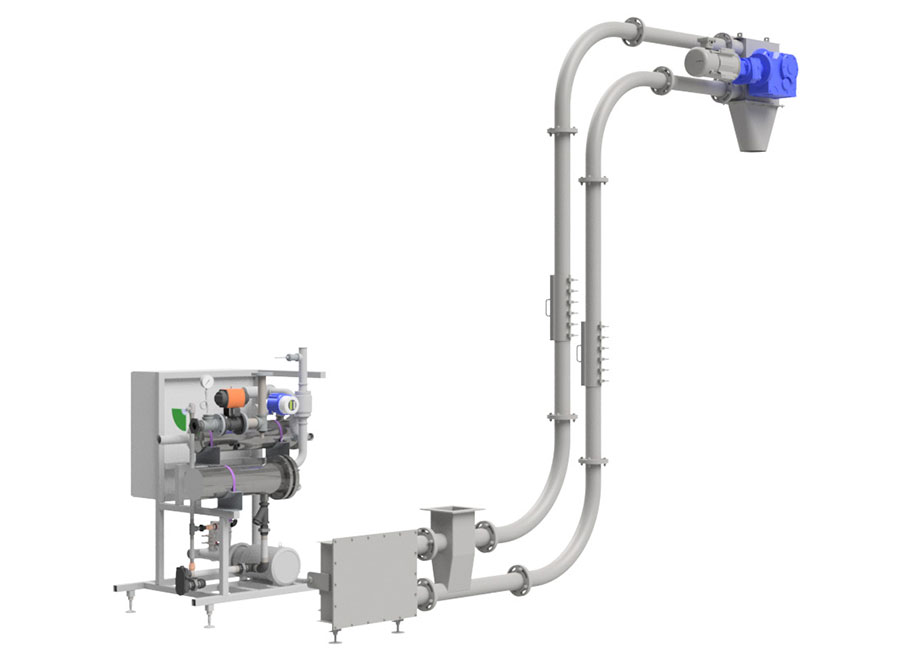

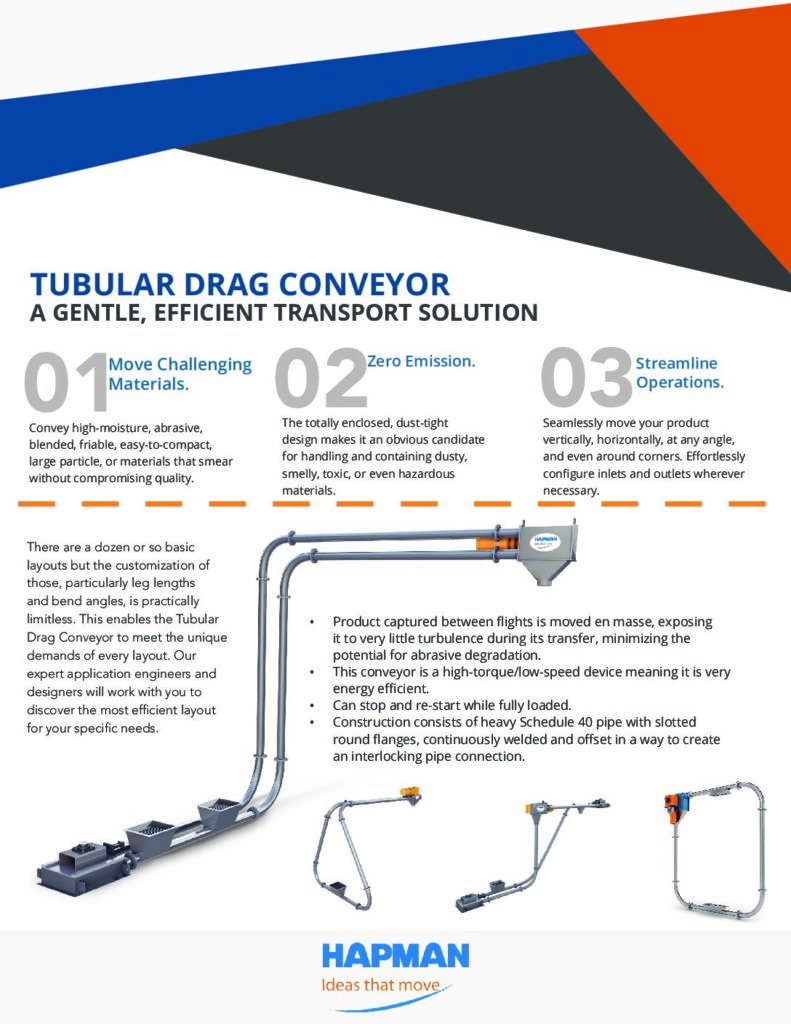

Layouts

There are a dozen or so basic layouts but the customization of those, particularly to leg lengths and bend angles is practically limitless. This enables the Tubular Drag Conveyor to meet the unique demands of every layout. Our expert application engineers and designers will work with you to discover the most efficient layout for your specific needs.