Equipment and Systems

Conveying, Bag Handling and

Processing Solutions

3,000+

Materials Tested

56

Countries

15,000+

Applications

200+

International companies

Services That Deliver Ideal Performance

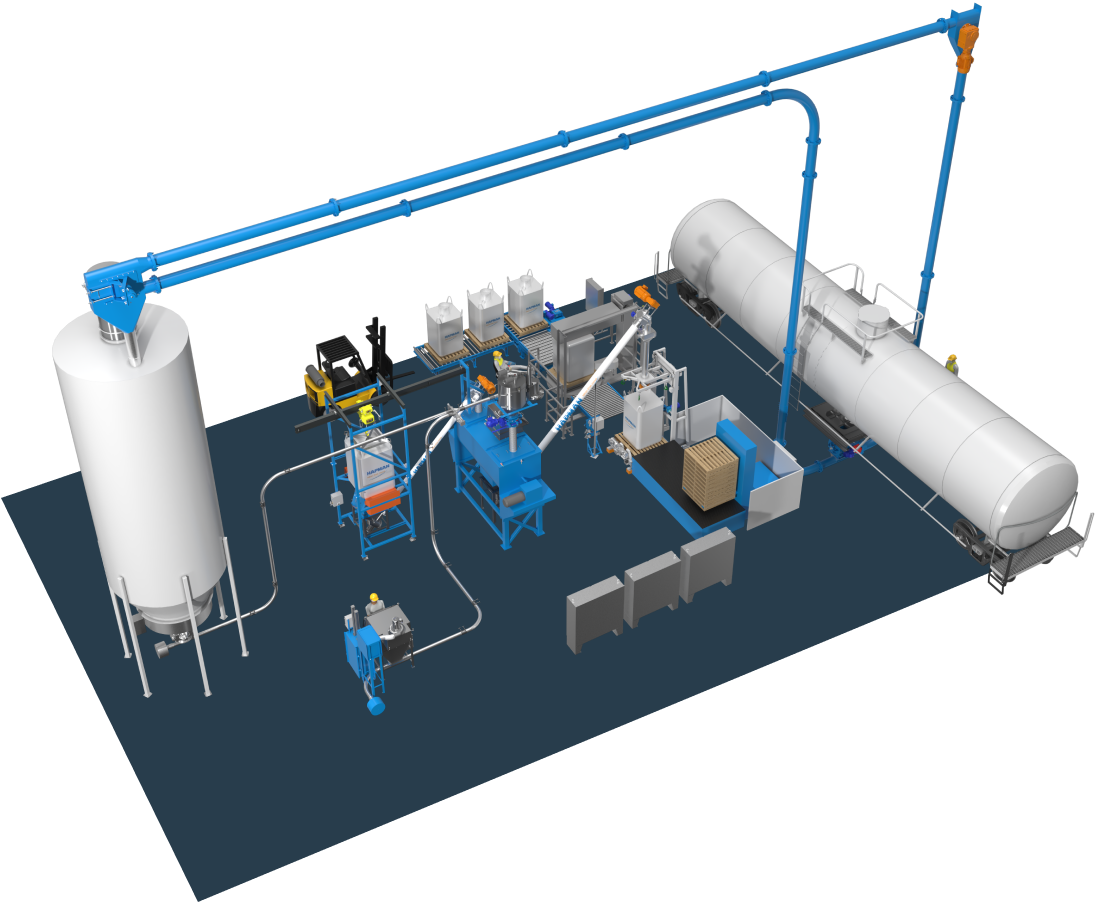

From initial application assessment through startup and maintenance, you can rely on a complete range of Hapman services to create equipment and systems that are guaranteed to meet your bulk material handling requirements.

Featured Application Expertise

See all Application ExpertiseOptimizing Seasoning Dispersion for Snack Food Leader

Discover how an industry-leading snack supplier leveraged Hapman’s precision feeding solutions to achieve flawless seasoning coverage.

Efficiency in Batching & Blending: 4 Common Challenges and How to Fix Them

There’s no single solution for any given material handling, batching, or blending application. Significant efficiency improvements require varying degrees of…

Transforming Pharmaceutical Efficiency with Innovative Conveyor Technology

PROBLEM: A leading pharmaceutical company approached Hapman for help in designing a vacuum conveyor system tailored to their needs. They…

Volumetric Vs. Gravimetric Feeder Operation

How Much Control Is Achieved with Volumetric vs. Gravimetric Material Feeding? Whether you work in the manufacturing or production industry,…

Featured Case Studies

See all Case StudiesHelix® Flexible Screw Conveyor Feeds Innovative Form-Fill-Seal Packaging Solution

Based in Grand Rapids, Michigan, IMS Group USA offers bulk solids packaging solutions for the food, pharmaceutical, resin, chemical and…

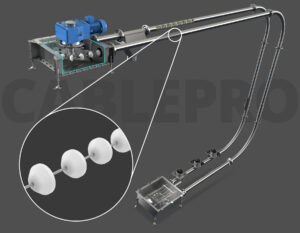

Issues of Unloading Ammonium Nitrate Prill are Eliminated with Tubular Drag Conveyor System

“Hapman and their local representative worked very hard to ensure the successful completion of our client’s project,” stated O’Connor. “Their…

Easy-to-Clean. Cost Effective. Trouble-free Operation. Helix® is the Top Choice for Specialty Dry Bulk Food Company

Planning for expansion is a critical step in a company’s growth plans. Especially when evaluating process improvements and new equipment…

Bulk Bag Filler – Plastics Manufacturer Uses Bulk Bag Filler FIBC System

CHALLENGE A plastics manufacturer needed a bulk bag filler that could be adjusted to fill a variety of large bag…

Bulk Density Guide

This resource provides the densities of thousands of bulk materials to assist in system design.

Find DensitiesConfigurators

Speed your designs with online CAD and BIM format files to configure 3D models and 3D PDFs.

Access FilesRequest a Quote

Tell us about your specific application need to start the quote process.

Let’s Get Going