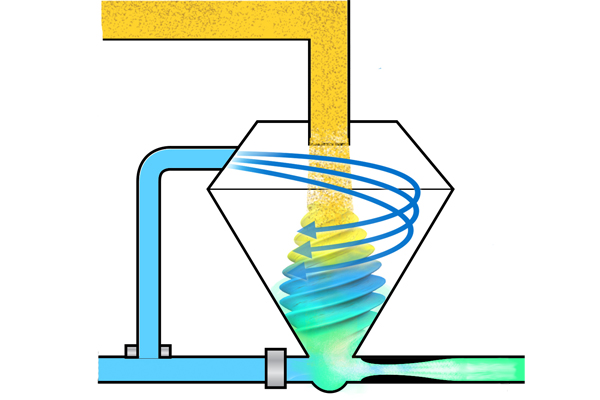

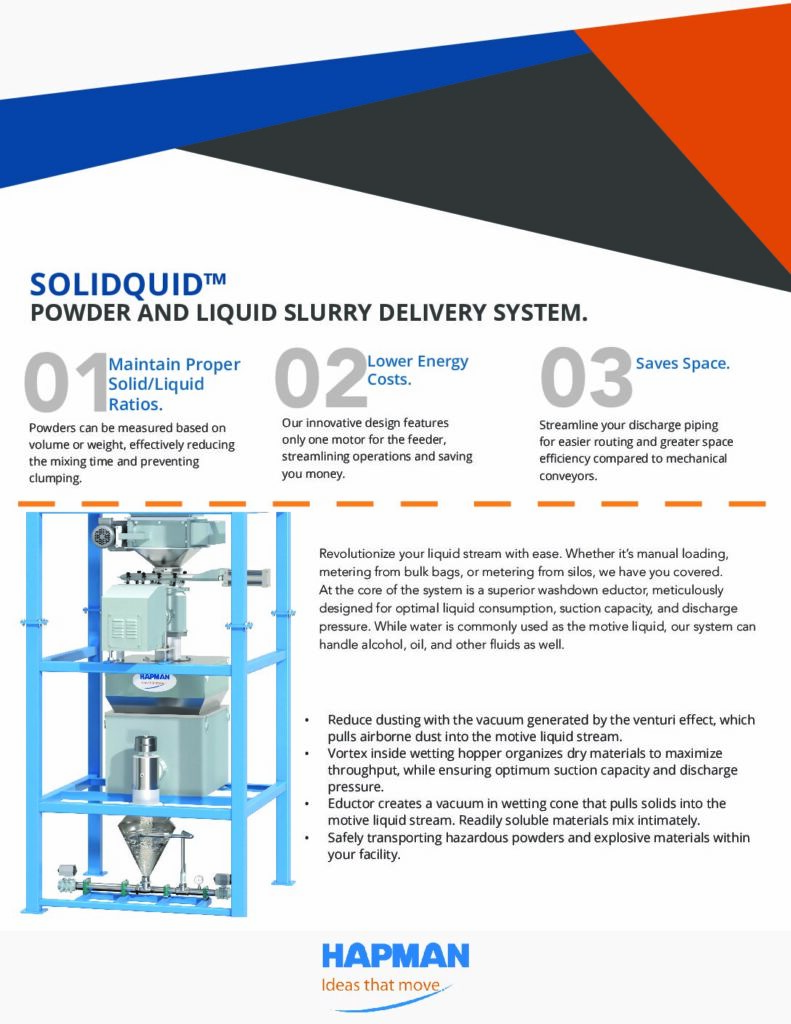

Innovative Wetting Cone Design

Solidquid™ boasts an unparalleled wetting cone system that expertly meters powder into the mixing chamber. Its self-cleaning mechanism ensures that materials never cling to the sides of the hopper—guaranteed consistency in every cycle.