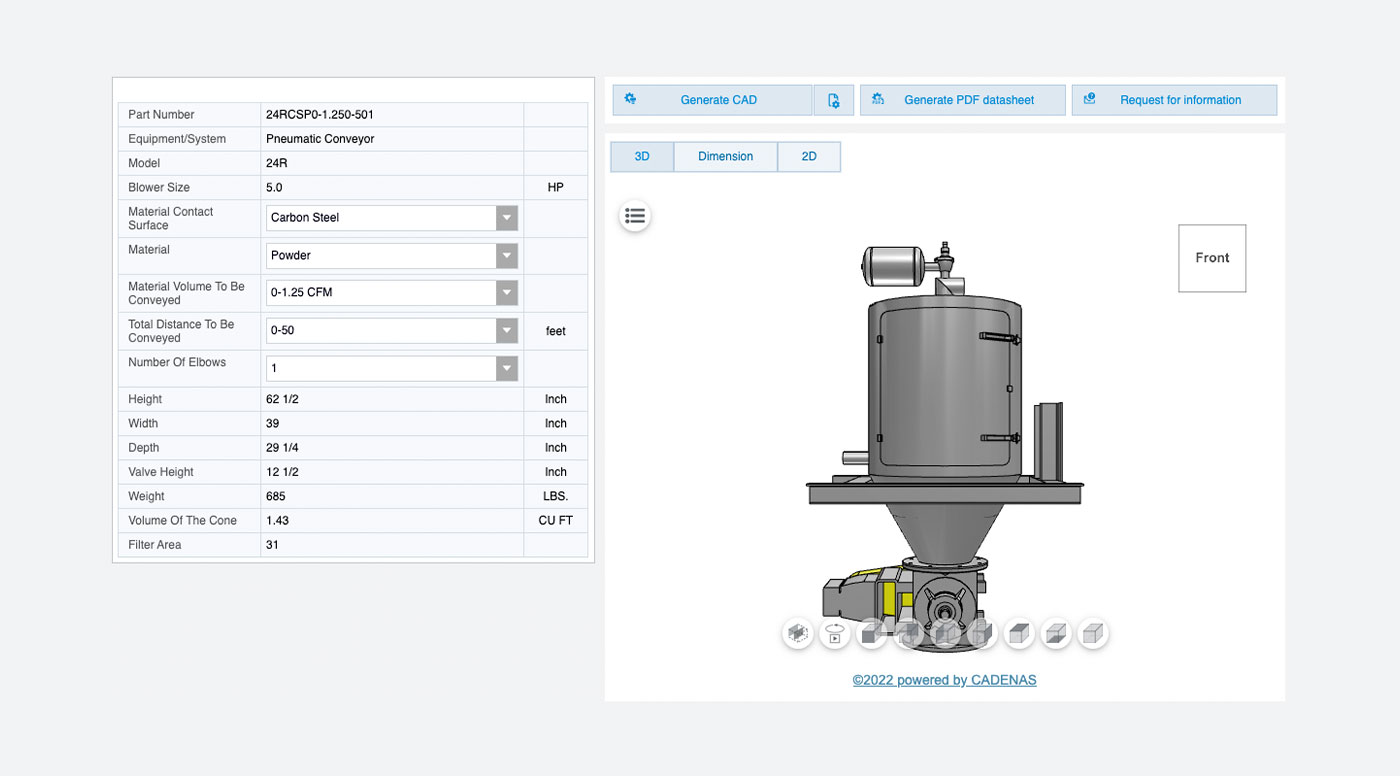

MiniVac

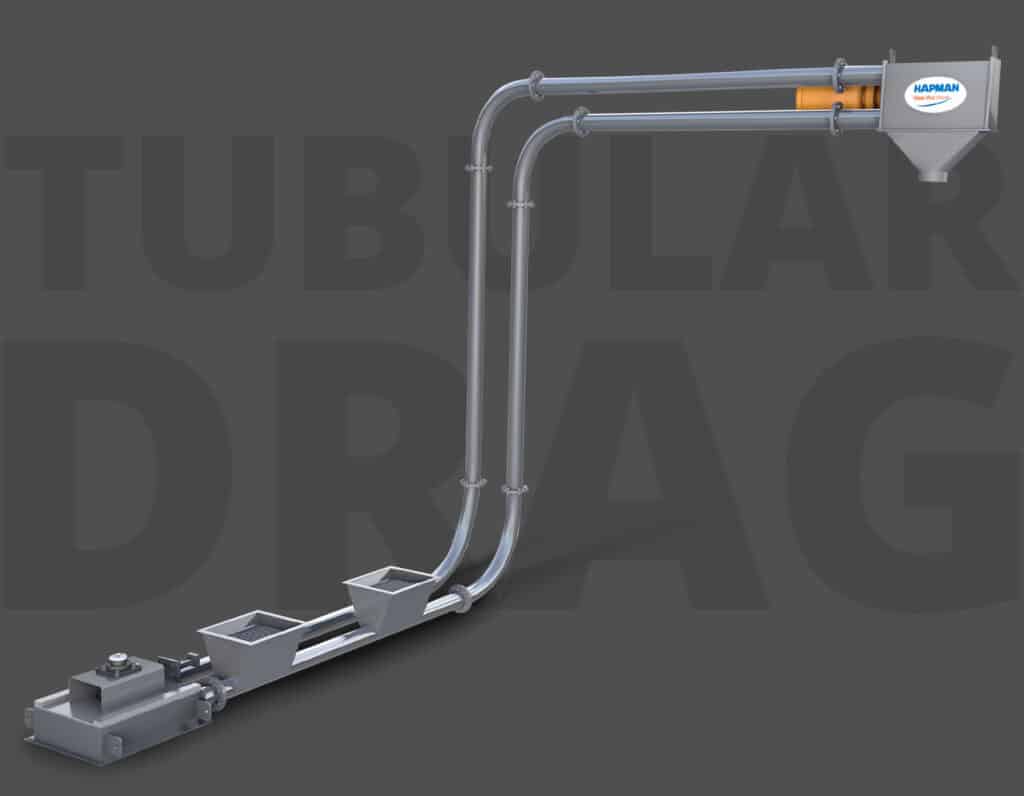

- Dilute phase vacuum introduces material into a high velocity air stream.

- The vacuum conveyor moves material vertically, horizontally, around corners, on multiple levels and long distances with minimal operator attention or maintenance.

- Available in 304 and 316 stainless steel or carbon steel