Hoist and Trolley

- 1-ton or 2-ton hoists and trolleys are available.

- Load-tested and certified bag adapters.

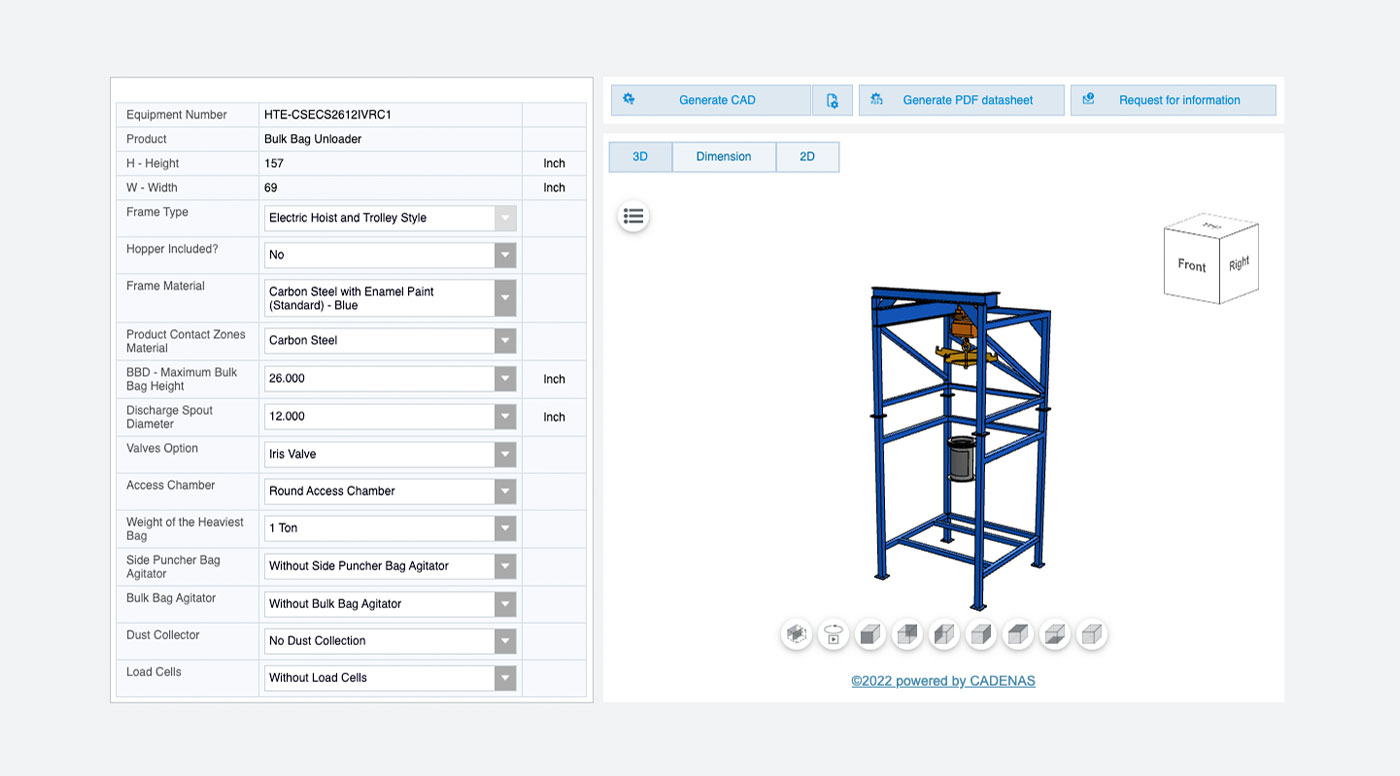

Engineered with heavy-duty 3″ tubing construction for durability. Its adjustable heights accommodate various bag sizes effortlessly. With a wide range of add-ons available, customization is seamless to suit any application. Enhance productivity with integrated features such as dust control systems and vibration devices.

Use the Hapman Configurator for on-demand access to design custom solutions for your application and immediately obtain reference models and drawings.

Our Performantee is a 100% operational guarantee that you will be fully satisfied with the performance of our equipment, and that it will achieve the specific results for which it was designed and manufactured. If not, we will revise or repair it to deliver the results we promised.

Have Technical Questions About Our Bulk Bag Unloaders?