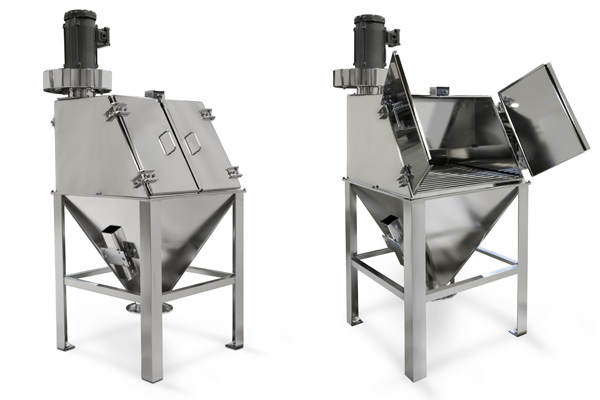

SR Series Dust Collector

- Side access door provides easy filter removal.

- Compact, single cartridge filter design.

- Removable air baffle.

Our Bag Dump Station is engineered to capture even the finest airborne particles, leaving nothing but clean air behind. Boasting an automatic reverse pulse-jet filter system, this self-cleaning marvel reduces downtime and slashes maintenance costs, guaranteeing consistent, worry-free operation. Hapman’s bag dump station fits immaculately with an array of conveyors, mixers, and other pivotal processing equipment, offering you a cohesive solution tailored for excellence in material handling.

Our Performantee is a 100% operational guarantee that you will be fully satisfied with the performance of our equipment, and that it will achieve the specific results for which it was designed and manufactured. If not, we will revise or repair it to deliver the results we promised.

Have Technical Questions About Our Small Bag Dump Stations?