CHALLENGE

A casting foundry wanted to create a cleaner, more efficient environment that was also safe for workers.

CUSTOMER

Ross Casting and Innovation, LLC (RCI)

INDUSTRY

Casting

BUSINESS BENEFITS REALIZED

Eliminated dusting – Reduced equipment maintenance issues

Potential revenue from waste

Additional recycling opportunities

Reduced noise levels – created a better working environment for employees

Improved worker safety – Reduced turn-over and cost of claims

For more than 75 years, Ross Casting and Innovation (RCI) has been creating aluminum castings for the military, aerospace and automotive industries – just to name a few. Today, the company is a leading producer of turbocharger wheels. The foundry’s manufacturing process involves pouring molten metal into plaster molds, then knocking out the plaster to reveal the finished metal product.

When RCI consolidated several facilities into a single new building early in 2009, it wanted to be known for more than just its quality metal products. So, it set out to create a new kind of foundry – one that was clean and pleasant to work in.

“Typically people think of foundries as dark, noisy, dirty places,” says RCI Director of Engineering Brad Hohenstien. “We wanted to change that perception.”

CREATING A NEW KIND OF FOUNDRY

The purpose of creating a clean, quiet foundry was two-fold. First, RCI wanted to solve the maintenance problems frequently created by plaster dust in the facility.

“The dust and dirt in the facility can get into the process and cause problems with the equipment,” says Hohenstein. “We’re working with gypsum, which is a powdery white material. It’s not dangerous, but the dust gets everywhere. It can soak up the oil on parts that need lubrication and create a lot of maintenance issues.”

In addition, RCI wanted to make the foundry a better place to work, and in doing so decrease employee turnover and training costs.

“In foundries employee turnover is a common issue, so by keeping our facility clean and quiet we’re improving employee retention and perception,” says Hohenstein.

MAKING A SAFE BET

The system RCI wanted to create would be unique and complex, so the company knew it needed a equipment manufacturer capable of engineering a quality, custombuilt solution. They began their search on the Internet and discovered most solution providers either provided vacuum conveyors or drag conveyors – but not both. When RCI discovered Hapman, a world leader in material handling systems, they were pleased the company offered both types of conveying systems.

“The conveyor companies told us a conveyor system was the way to go, and the vacuum companies told us we needed a vacuum system,” says Hohenstein. “We wanted to find a company that sold both systems so they could give us an unbiased opinion.” In the end, RCI decided to choose Hapman because of its Performantee™ – a performance guarantee that ensures Hapman systems will achieve the results they are designed to produce. “Because this was a custom-designed system we knew there would probably be some issues we needed to work out,” says Hohenstein. “Knowing that Hapman would continue to work on the system until it was performing at 100 percent was critical to our decision-making process.”

“The conveyor companies told us a conveyor system was the way to go, and the vacuum companies told us we needed a vacuum system,” says Hohenstein. “We wanted to find a company that sold both systems so they could give us an unbiased opinion.” In the end, RCI decided to choose Hapman because of its Performantee™ – a performance guarantee that ensures Hapman systems will achieve the results they are designed to produce. “Because this was a custom-designed system we knew there would probably be some issues we needed to work out,” says Hohenstein. “Knowing that Hapman would continue to work on the system until it was performing at 100 percent was critical to our decision-making process.”

ENGINEERING A SOLUTION

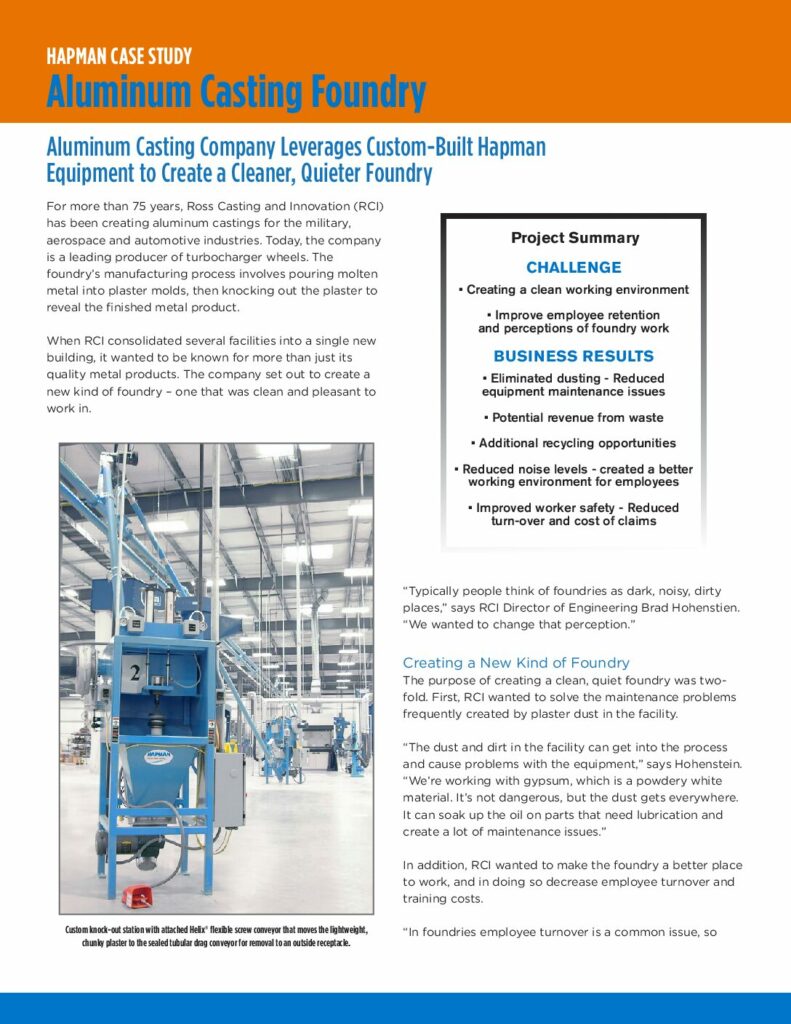

The engineering team at Hapman worked closely with RCI to design a solution that achieved their dust and noise reduction goals. The system Hapman designed begins with five knock-out stations that vibrate the molded parts, breaking the plaster surrounding them apart. The plaster then falls down into a hopper, while the dust created during this process is contained in dust-collection systems above the knockout stations. The stations are also lined with sound-deadening panels to significantly reduce the noise this process produces.

From the hoppers, elevating Helix® conveyors carry the broken plaster up to the ceiling, where it empties into a 400 ft (122 m) Tubular Drag Conveyor. The Tubular Drag Conveyor then carries the waste out of the building and empties it into roll-off collection containers.

In addition to reducing noise and dust, the new system was also engineered to create other benefits. Added safety features reduce the risk of employee injury at the knock-out station. Plus, the new system keeps waste metal out of the plaster, creating recycling potential.

“Because the new system does a better job at separating the waste metal and the plaster, it allows us to investigate opportunities for recycling the plaster,” says Hohenstein. “In the future, we might be able to sell it to someone else for a different use.”

ACHIEVING A VISION

As Hohenstein expected, there have been a few issues to work out along the way. The lightweight, chunky plaster has a tendency to clog things up and resist the pull of gravity. Hapman responded with several modifications to the system to combat these effects.

The result: RCI has been able to achieve its vision of creating a better foundry – one that produces the high-quality products its customers expect while providing workers with a clean, safe, quiet environment they will appreciate for years to come.