CHALLENGE

A fully operational research laboratory needed a better way for technicians to remove and dispose of more than 1,200 pounds of soiled animal bedding per day.

CUSTOMER

Uniformed Services University of the Health Sciences, Bethesda, MD

INDUSTRY

Educational training facility for U.S. Military

BUSINESS BENEFITS REALIZED

Improved workflow with an ergonomic way to empty waste bedding from cages and feed material into the conveyor.

Provided odor control and eliminated potentially hazardous exposure to employees.

The Uniformed Services University of the Health Sciences, (USUHS), is located in Bethesda, MD and operates as a pathway to train, educate and prepare uniformed services health professionals, officers and leaders to directly support the Military Health System, the National Security and National Defense Strategies of the United States, and the readiness of the Armed Forces.

A DANGEROUS, HEAVY LOAD FOR LABORATORY WORKERS

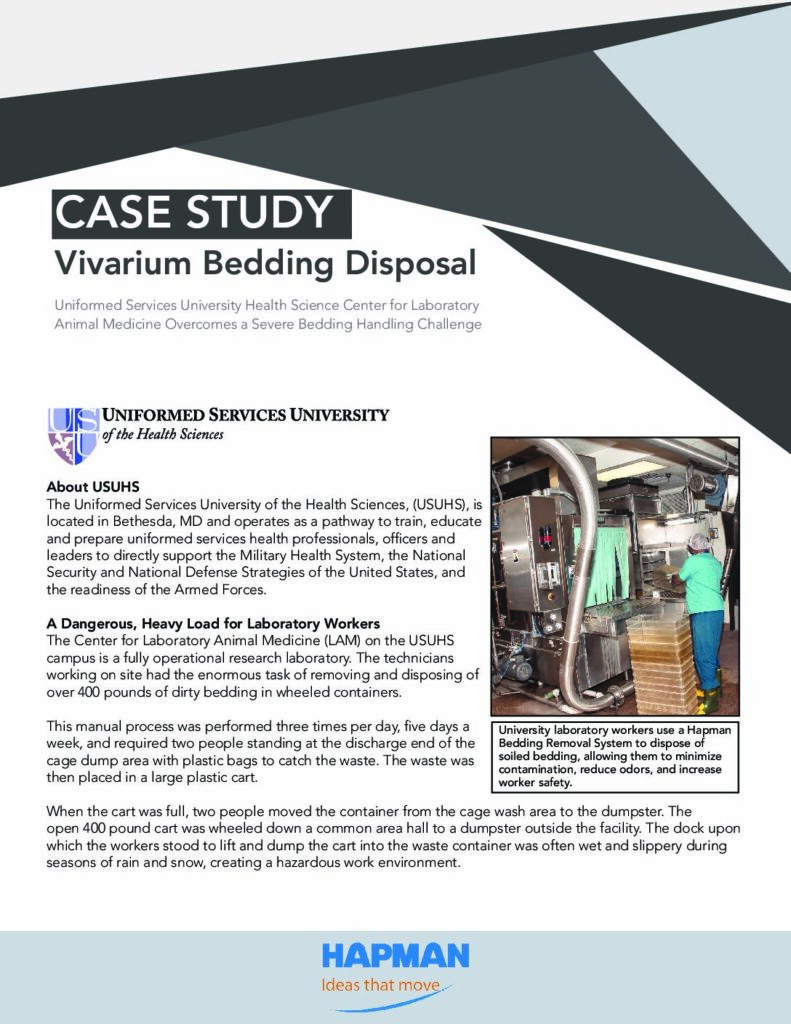

The Center for Laboratory Animal Medicine (LAM) on the USUHS campus is a fully operational research laboratory. The technicians working on site had the enormous task of removing and disposing of over 400 pounds of dirty bedding in wheeled containers.

This manual process was performed three times per day, five days a week, and required two people standing at the discharge end of the cage dump area with plastic bags to catch the waste. The waste was then placed in a large plastic cart. When the cart was full, two people moved the container from the cage wash area to the dumpster. The open 400 pound cart was wheeled down a common area hall to a dumpster outside the facility. The dock upon which the workers stood to lift and dump the cart into the waste container was often wet and slippery during seasons of rain and snow, creating a hazardous work environment.

This manual process was performed three times per day, five days a week, and required two people standing at the discharge end of the cage dump area with plastic bags to catch the waste. The waste was then placed in a large plastic cart. When the cart was full, two people moved the container from the cage wash area to the dumpster. The open 400 pound cart was wheeled down a common area hall to a dumpster outside the facility. The dock upon which the workers stood to lift and dump the cart into the waste container was often wet and slippery during seasons of rain and snow, creating a hazardous work environment.

Another challenge with this process was the odor from the carts as they were rolled down the hall – leading to numerous complaints from students and faculty. In addition, there was great concern from LAM management about the potential exposure of zoonotic materials to people passing through the lab’s corridors.

NOT ALL CONVEYORS ARE CREATED EQUAL

Prior to the manual dumping procedures, the LAM used a vacuum conveying system for automated bedding removal. The system was removed several years after installation because of excessive downtime and maintenance. The vacuum conveying system was not designed to handle the waste bedding and would continually clog. The maintenance team at USUHS spent countless labor hours unclogging and fixing the conveyor, only to repeat the emergency repairs a short time later.

A CONVEYOR ENGINEERED SPECIFICALLY FOR HANDLING BEDDING

USUHS and the laboratory personnel knew a change had to be made to the labor intensive manual handling of the animal bedding. After some research of bedding handling systems, coupled with the previous failed experience with vacuum conveying, Aladino Robles, Chief of LAM’s facility operations found the tubular drag conveyor. The conveying technology, invented and manufactured by Hapman, is designed specifically to address the unique challenges of bedding handling. The Hapman bedding handling system included a cage dump station and tubular drag conveyor.

USUHS and the laboratory personnel knew a change had to be made to the labor intensive manual handling of the animal bedding. After some research of bedding handling systems, coupled with the previous failed experience with vacuum conveying, Aladino Robles, Chief of LAM’s facility operations found the tubular drag conveyor. The conveying technology, invented and manufactured by Hapman, is designed specifically to address the unique challenges of bedding handling. The Hapman bedding handling system included a cage dump station and tubular drag conveyor.

The cage dump station gave LAM workers an ergonomic way to empty waste bedding from cages and feed the soiled material directly into the conveyor. The conveyor – a sealed stainless steel tube that provides for odor control and elimination of potentially hazardous exposure from bedding transport – quietly moves the bedding from the lab area down the long 250 ft. corridor out to the bay area dump container.

The new system quickly improved working and environmental conditions within the facility. Robles noted, “We no longer openly move potentially unsanitary material through common areas, and our technicians don’t have to bear any heavy weight while carefully navigating the loading docks.” The animal laboratory at USUHS has seen the value in the Hapman bedding handling system in just three short months. Robles enthusiastically commented, “We move up to 1,200 pounds of animal bedding per day. This system is a great purchase for LAM and the university.”

For more information on customizable Hapman bedding disposal or bedding feed dispensing systems designed specifically engineered for vivarium applications e-mail sales@hapman.com, or visit www.hapman.com.