Efficient Material Handling with Vacuum Conveyors

In bulk material handling, efficiency and versatility are paramount. Vacuum Conveyors are designed to optimize material movement across various sectors, ensuring cost-effective and reliable operations. Key Features of Hapman Vacuum…

Speed Meets Manufacturing Needs

In today’s fast-paced manufacturing world, adaptability is key. Hapman understands this, which is why we’re excited to highlight our Quick-Ship program for Helix Flexible Screw Conveyors. This innovative solution is…

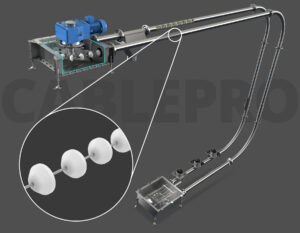

Revolutionizing Food Conveyance: Hapman’s CablePro™ Tubular Drag Conveyor

Unveiling Innovation at PACK EXPO 2024 In the dynamic world of food processing and packaging, innovation is the key to maintaining product quality and operational efficiency. Hapman, a renowned leader…

Hapman Launches New CablePro™ Conveyor at PACK EXPO 2024

Unveiling the CablePro™ Tubular Drag Conveyor Hapman, a global leader in custom bulk material handling equipment, made a significant impact at PACK EXPO 2024, held from November 3-6 at McCormick…

Elevating Material Handling Efficiency with the Helix® Flexible Screw Conveyor

In material handling, reliability and adaptability are key to maintaining smooth operations across industries. Since 1977, Hapman’s Helix® Flexible Screw Conveyor has been a trusted solution for businesses seeking efficient…

Eductors: What Are They and How Do They Work?

When creating a fluid or pneumatic conveyor system, eductors can be a good options in place of fans, blowers, and pumps. Eductors are jet pumps to create a vacuum that can…

Using Material Handling Automation to Improve Efficiency

Take a closer look at three main types of material handling automation and the Hapman difference in designing and integrating automation systems.

Challenges in Conveying Bulk Materials

When plants deal with bulk material well, all of their operations become easier. But challenges in bulk material handling lead to many problems, including inefficiencies, degradation and material segregation. Plants…

3 Reasons Why a “Regular” Flexible Screw Conveyor Might Not Work for You

Manufacturers commonly use flexible screw conveyors because of their low cost, reliability, straightforward operation and simple construction. This equipment is not complicated, but it should not be cookie-cutter either. Poor performance, excessive…

USDA Certified Or 3-A, Which Is The Best?

When purchasing equipment for facilities involved in the manufacturing or processing of dairy products, there is often confusion between the designations of USDA Acceptance Certified and 3-A Approved equipment. To…

Small Dust Control Saves Big by Mitigating Risk

Dust control and risk mitigation go hand-in-hand for manufacturers who processes dry powders and other bulk materials. NFPA 654 Standard for the Prevention of Fire and Dust Explosions from the…

Volumetric Vs. Gravimetric Feeder Operation

How Much Control Is Achieved with Volumetric vs. Gravimetric Material Feeding? Whether you work in the manufacturing or production industry, you need the right feeder system to regulate the flow…

The 6 Key Considerations for Selecting the Right Conveyor System

Selecting a conveyor system for a batch or continuous processing application is not always as straightforward as you may think. In fact, it almost never is. Moving material consistently – at…

5 Reasons to Avoid Round-Link Chains in Tubular Drag Conveyors

Tubular drag conveying is a common method of moving loose bulk materials between processes in industrial plants. Chain-type tubular drag conveyors fall into two basic categories: those that use round-link chains and…

How to Keep Your Industrial Business Safe from Dusting

Benjamin Franklin was an author, inventor, politician and one of the Founding Fathers of the United States. He may also have had the uncanny ability to see into the future…

How to Maximize Productivity with the Right Design of Your Flexible Screw Conveyor

Flexible screw conveyors are one of the most common types of conveyors used by manufacturers because of their low cost and simple construction. Although it isn’t a complicated piece of…

Selecting a Conveyor for Effectively Moving Bulk Materials

Although selecting the right conveyor for your bulk material handling application may seem fairly straightforward, oftentimes that is not the case. There are many factors that come into play when…

How the “Bend But Don’t Break” Principle Applies to Tubular Drag Conveyors

If you’re a sports fan, you know that the term “bend but not break” refers to a football defense that gives up yardage but doesn’t allow the opponent into the…