Helix® Flexible Screw Conveyor

- Conveniently convey bulk material up to 25 cfm.

- Available in 2.5” to 8” diameter sizes.

- Quick-Ship (ship in 48 hours).

A flexible screw conveyor (also known as a Helix conveyor, spiral conveyor, screw conveyor, or auger conveyor) is a type of mechanical conveying system that uses a helical screw or non-fixed shaft auger enclosed within a tube. As the screw rotates, it effectively moves materials from the lower intake (feed) point to the elevated discharge point. It stands out by offering a balance between performance and cost-effectiveness, with quick delivery, making it a smart choice for modern bulk material handling.

► Space-Efficient Design: Their unique structure allows these conveyors to navigate tight spaces and around obstacles, maximizing available floor space.

► Versatility: Capable of handling various materials, flexible screw conveyors are excellent for material transportation as well as batching and blending applications.

► Easy Installation: With fewer parts and a straightforward design, these conveyors are simple to install. Their forgiving design allows major equipment to be placed first, with the Helix then positioned as needed—offering far more flexibility in choosing the ideal locations for both inlet and discharge.

► Low Maintenance: The enclosed design minimizes material spillage and wear, leading to lower maintenance costs and increased operational longevity.

The Hapman Helix® flexible design adapts effortlessly to your facility’s layout, ensuring efficient and consistent material movement. With standard T-handle couplings, you can disassemble this conveyor in just minutes for easy cleaning and minimal downtime making the Hapman Helix perfect for applications in food processing, pharmaceuticals, chemical manufacturing, and more.

Integrate the Helix® Flexible Screw Conveyor with other bulk material equipment from Hapman like the Bulk Bag Unloader, PosiPro™ Feeder, or Bag Dump Stations for a complete conveying system.

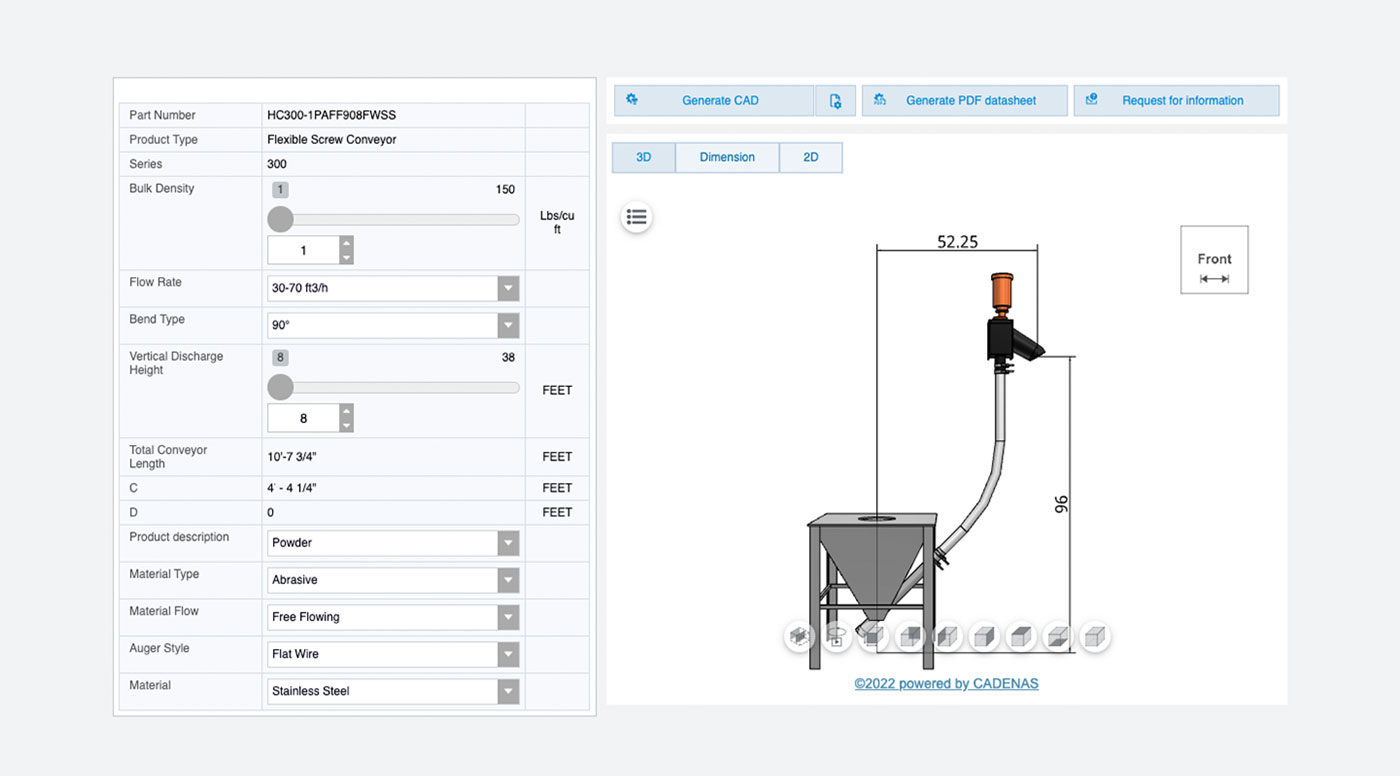

Use the Hapman Configurator for on-demand access to design custom solutions for your application and immediately obtain reference models and drawings.

Quick-Ship Ships in 2 Days or Less!

We designed our Hapman Helix Flexible Screw Conveyors to provide customers with an economical conveying method that can be used for most types of dry material handling applications.

Our Performantee is a 100% operational guarantee that you will be fully satisfied with the performance of our equipment, and that it will achieve the specific results for which it was designed and manufactured. If not, we will revise or repair it to deliver the results we promised.

Have Technical Questions About Our Helix Flexible Screw Conveyors?