“Hapman and their local representative worked very hard to ensure the successful completion of our client’s project,” stated O’Connor. “Their efforts helped identify and implement the optimum solution in order to meet our client’s needs on schedule, scope, and budget.”

The Art and Science of Handling Controlled, Functional Explosive Material

Dyno Nobel manufactures explosives and offers explosion management services to customers in mining, oil and gas exploration, fertilizers, construction, and concrete and building materials. The core of Dyno Nobel’s operation is manufacturing Ammonium Nitrate Prill in bulk and safely transporting it in specially designed trucks to the point of use. When the company decided to shift its plant in Donora, PA from a manufacturing facility to a distribution hub, plant engineers knew the transition would require a safe, automated way to o-load the bulk material from railcars.

The system previously used for the rail car unloading consisted of screw conveyors, bucket elevators, and belt conveyors. The system was very inefficient, created an unacceptable level of product degradation, and became a maintenance problem.

Partnerships Bring Project Success

To assist with this process, Dyno Nobel hired Venture Engineering, a multi-faceted engineering firm that provides clients with front-end feasibility studies through design and construction. “Very early on during our first visit and inspection”, stated Kevin O’Connor, Venture Engineering’s Project Manager, “we realized that their existing equipment was totally inadequate for the goals of the system and the rates required.” Several Venture engineers had experience with Hapman and the Tubular Drag Chain Conveyor for use in applications with demanding variables. Due to the schedules of product delivery, and the inadequacy of their existing system, Dyno Nobel was “truly in an emergency mode to find the right solution,” stated O’Connor.

Engineering, operators, and management worked together to understand the needs and challenges the conveyor would face in the Ammonium Nitrate Prill unloading application. For this project, and for the material being handled, several considerations required addressing. First and foremost the system must handle the prill as gently as possible, maintaining the integrity of the product. The performance of the ammonium nitrate, for its intended purposes, requires that the material remain in prill form. Multiple transitions from conveyor-to-conveyor, or rough handling of the material will cause the prill to degrade thereby reducing the value of the product. The second consideration is that the system must be dust-tight. Allowing outside elements in, or inside elements out is not acceptable. Third, the system must be able to start and stop under a full load of material. And finally, the installed system must be absolutely dependable. “Due to the requirements of this project, we determined early in the feasibility process that the Hapman Tubular Drag system was the only way to go,” continued O’Connor.

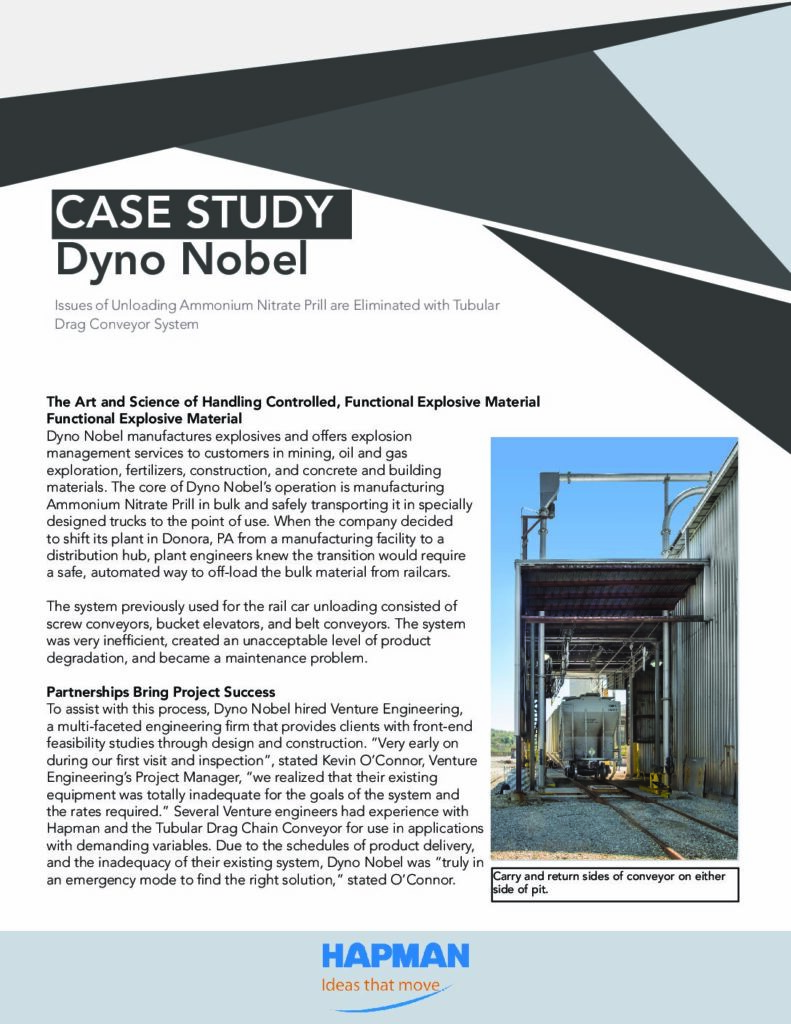

Hapman designed a stainless steel Tubular Drag Chain Conveyor in a gooseneck circuit. The conveyor housing is constructed of 8” diameter sch. 40 stainless steel piping. Inside the fully sealed housing, the chain consists of stainless steel sealed-pin design with a 6” pitch and U.H.M.W. polyethylene flights on 12” centers.

The stainless steel provides the necessary corrosion resistance and the heavy-duty chain selection allows the conveyor to easily start and stop under full load, a critically important feature when unloading rail or truck cars. The process of loading and unloading of bulk material poses variables that may not exist for an in-plant operating condition. To ensure the material was not exposed to the open air upon discharge from the railcar, the engineers at Hapman sourced an air-driven interface assembly. With the push of a button, operators activate the sleeve and easily attach it to the railcar discharge. The interface assembly provides a safe, sealed discharge for material to flow. From the railcar the material flows into an 18“ dia. rotary feeder, located in the underground pit below the tracks, which control feeds the ammonium nitrate into the Tubular Drag. The conveyor then elevates the material nearly 83’ and moves it horizontally another 54’. The material is discharged onto a belt conveyor for final distribution in the storage building.

Hapman provided a complete turnkey system wherein fell the responsibility for the removal of the old system, the engineering and design of the new, as well as the installation, start-up and commissioning. “The system is living up to expectations and more,” notes Matt Graves, Plant Manager at Dyno Nobel. Upon arrival of the conveyor, Graves and others at the plant were unsure if the system would work in their application. “The flights were smaller than the pipe and I did not think it would work”, Graves explained. All operating concerns were quickly dispersed as the Tubular Drag Chain Conveyor began to e

ciently move the Ammonium Nitrate Prill from the railcar into the storage silo.

Delivering Effective Bulk Material Railcar O-Load

The railcar o-load system at Dyno Nobel is a success because each party involved in the engineering, design, implementation and start-up worked together to understand the challenges of the application. The engineers at Hapman took those challenges and applied more than 70 years of bulk material handling experience to design the most comprehensive, fully automated conveying system. The number of chain and flight options offered in the Hapman Tubular Drag Chain Conveyor allowed designers to select the chain that would be corrosion resistant and not permit material to get trapped in the knuckles of the chain. The conveying system provided the safe, gentle handling, trouble-free, and effective bulk material o-load which Dyno Nobel was seeking. “Hapman and their local representative worked very hard to ensure the successful completion of our client’s project,” stated O’Connor. “Their efforts helped identify and implement the optimum solution in order to meet our client’s needs on schedule, scope, and budget.”