Summary

The proper selection and sizing of a conveyor is critical to successfully meeting production goals. The key factors that should be evaluated when choosing a conveyor are; material, operation, environment, envelope, cost, an history. Taking the time upfront to understand these factors and gather the most accurate data possible related to each component will ultimately make the selection of conveying technology the best for your specific needs and offer the greatest return on investment.

Introduction

Selecting a conveyor system for a bulk material handling application is not always as straightforward as one might think. Moving material consistently, at a rate that is inline with production requirements, and in a manner that does not contribute negatively to the plant operating environment, such as dusting or increased maintenance, can be a challenging endeavor for process engineers and procurement personnel.

Often, conveyor systems are misapplied because of the overall plant’s desire to keep the number of unique pieces of equipment to a minimum while also adhering to spending limits. These factors are critical to consider when selecting a conveyor system for a material handling application; however, they should not be the first, or the only, evaluation metrics used.

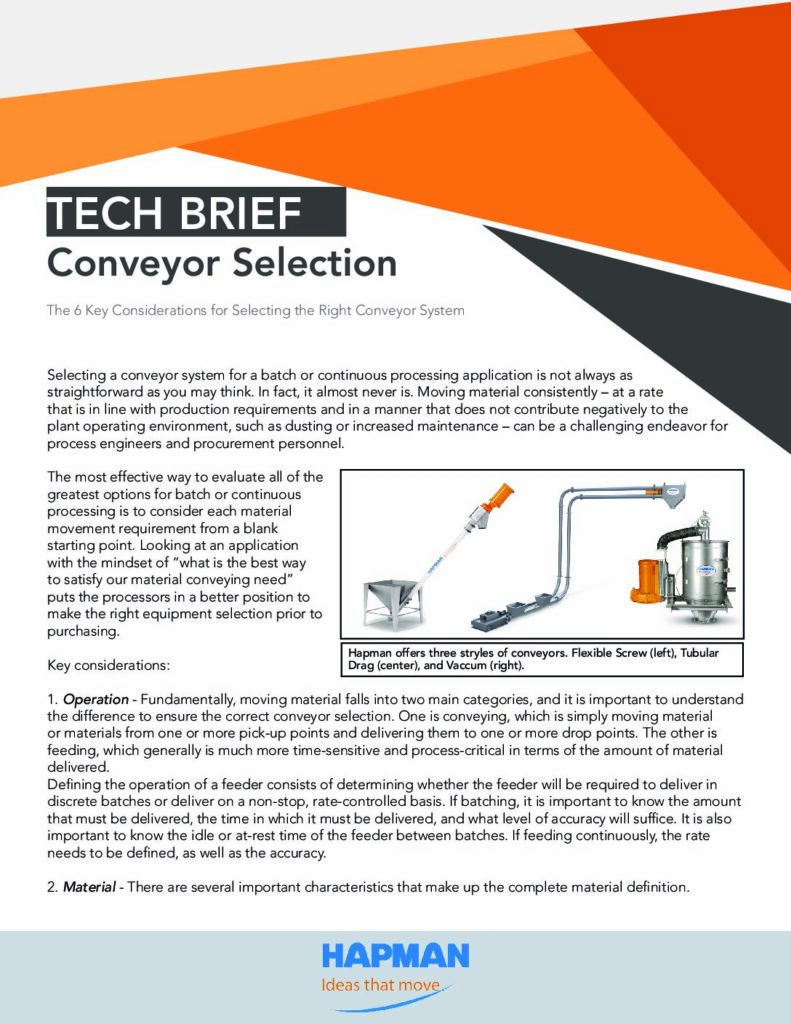

The most effective way for a processor to evaluate all of the best options for a material handling application is to consider each material movement requirement from a blank starting point. Looking at an application with the mindset of “What is the best way to satisfy our material conveying need,” will put processors in a better position to make the right equipment selection prior to purchase. Taking this stance, there are several key considerations to evaluate for proper conveyor selection, including material, operation, environment, envelope, cost, and history.

Material

There are several important characteristics that make up the complete material definition, which should be understood in their entirety. Some of these are dynamic and can influence or may be influenced by one or more of the other characteristics, so it is always recommended to look at them together.

1. Name of the material (many materials are known by more than one name)

a. An Esoteric or Trade Name (such as SnoMelt)

b. Generic Name (such as salt) or Chemical formula, which is defined & called by its primary ingredient or ingredients (sodium chloride, NaCl).

2. Material form or state in which it must be handled

a. Solids (free flowing or semi-free flowing)

i. What is the loose bulk density? (lbs/ft³, g/cc, kg/m³)

ii. Loose Bulk Density is commonly interchanged or confused with Specific Gravity but should not be. They are very different. Specific gravity is the weight per given volume of a substance, usually in its most natural, concentrated, unreduced solid form (no air pockets or interstitial spaces between particles). Loose Bulk density is the weight per given volume of the material in its reduced, free-flowing or semi free-flowing state.

3. Solid Composition

a. Powder

b. Prill

c. Granule

d. Pellet

e. Fiber

f. Flake

4. Particle Size a. Symmetrical Solids are usually described in terms of their ability to pass through a screen of a certain size. b. Asymmetrical Solids are usually described in terms of their geometric dimensions, minimum and maximum.

5. Flowability – Flowability is perhaps the most important characteristic of any solid material to understand, yet it lacks a single standardized method of measurement across industrial disciplines

a. Most often it is defined in somewhat arbitrary terms as Very Free Flowing, Free Flowing, Average Flowability or Sluggish.

b. Angle of repose is also frequently used as an indicator of flowability. It is simply the natural angle or rate of incline that is observed when material is metered from a single discharge point without vibration or any effort to settle or distribute the accumulating mound.

c. Some use a 1 to 4 or 1 to 10 indexing system in an attempt to quantify the flowability.

d. We recommended reading the following document to better understand flowability. It’s co-written by James K. Prescott and Roger A. Barnum of Jenike & Johanson and published in the October 2000 issue of Pharmaceutical Technology. It’s downloadable from the Jenike & Johanson website at: http://info.jenike.com/technical-papers/on-powder-flowability

e. If the material is known or suspected to be a challenge because of its flowability, it may be best to send a sample to the equipment supplier for review.

6. Abrasiveness

a. Like flowability, abrasiveness lacks a universal standard definition. However, there are two material factors that tend to determine the abrasive quality. First is the material hardness, which is measurable and can be defined using the Mohs scale or Vickers scale. The second factor is the particle shape. A hard particle having no abrupt edges (a sphere) is less likely to abrade a contact surface than one with sharp edges. Most often, abrasive materials are known to plant personnel, and experience tends to be the most valuable measure. In other words, if a material has been found to erode other plant process equipment, certain parallels can be drawn and educated assumptions made as to the way the material will affect proposed equipment.

7. Material Temperature

a. Usually defined as a range (min. to max.)

8. Moisture Content

a. Usually described as a percentage by weight.

b. Can provide an important clue as to flowability or cohesiveness.

Note: One of the most common misconceptions in regard to materials and their various handling characteristics is that they can be obtained from MSDS (Material Safety Data Sheets). However, this is rarely the case. As the name implies, the document is a declaration of any health, safety or environmental concerns, and while it may offer some vague clues, it seldom enables a sufficient understanding of the way a material is likely to behave while being handled, stored or processed.

Note: There is an excellent resource printed on a web site called http://www.tankconnection.com/ which goes to extensive effort to quantify the most important characteristics for hundreds of common solids, assigning each a code and providing a convenient code chart for interpreting a material’s unique character profile.

That chart may be found at http://www.tankconnection.com/products/understanding-dry-bulk/ material-characteristics/.

Operation

Simply stated, operation refers to the function and performance that you need to satisfy. There are certain aspects of the operation that should include some detail and clarity.

Fundamentally, moving material through a process falls into two main categories. It is important for processors to understand the difference to ensure the right conveyor system is ultimately selected.

a. Conveying

b. Feeding

1. Conveying is simply moving material (or materials) from one or more pick-up points and delivering certain materials to one or more drop points. The rate at which this is accomplished is usually fixed and the delivery time, while important, fits comfortably within a minimum and maximum range. Conveyor systems are most often used as a refilling device for surge hoppers, feeders or process equipment.

a. Specifying the operation of a conveyor consists of:

i. Defining the amount of material that needs to be moved and the window of time within which it must be moved.

ii. In cases where there may be multiple discharge points, it is necessary to know the demand at each drop point.

iii. Determining what condition will initiate a refill, stop a refill and in the case of multiple discharges, develop suitable logic (or sequence of operation) to establish refill priority, so that the process is not inadvertently starved.

iv. When considering a single conveyor for multiple materials, it is imperative to know whether cross contamination will be an issue.

2. Feeding generally is much more time sensitive and process critical in terms of the amount of material delivered. Material is normally received from a single source and delivered to a single drop point. Because of the precision with which material needs to be delivered, delivery rates usually vary, either to coincide exactly with a continuously fluctuating demand or slowing to creep up on a batch-complete set point, for example.

a. Defining the operation of a feeder consists of determining whether the feeder will be required to deliver in discrete batches or deliver on a non-stop, rate-controlled basis.

i. If batching, it is important to know the amount that must be delivered, the time in which it must be delivered and what level of accuracy will suffice (usually defined as a +/-percentage of the target weight). It is also important to know the idle or at-rest time of the feeder between batches.

Ii. If feeding continuously, the rate needs to be defined, as well as the accuracy (usually defined as a +/- percentage of the instantaneous rate).

Note: One of the most frequently occurring mistakes with regard to conveyor or feeder sizing comes about as a result of confusing material usage with instantaneous demand.

For example, while a process may consume 1,000 pounds per hour of material, the conveyor or feeder may need to deliver at a rate that is 12 times higher if the batch needs to be satisfied in 5 minutes, for example.

Note: Most automatic means of feeding and conveying are sized according to the equipment’s volumetric capacity. However, the material demand is most often understood and communicated in terms of its weight. Therefore, a reliable value for the bulk density is necessary in order to calculate the volumetric requirement so that the equipment can be properly sized.

Environment

There are a number of environmental factors that must be considered in the proper selection of conveyor equipment. Some of these may combine with material characteristics to cause or exacerbate handling concerns, while others may necessitate added health and safety standards and countermeasures.

1. Some environmental factors may include:

a. Open sources of ignition

b. The potential for a flammable or explosive atmosphere

c. Corrosive vapor

d. High humidity

e. Temperature

f. Vibration

g. Pressure or vacuum (at inlet, discharge or both)

Envelope

The application of one device versus another quite often comes down to envelope – how much room is available to install the equipment or device. This appears straightforward, and yet this is one of the most frequently omitted pieces of information from inquiries.

1. When considering new equipment, particularly when some portions of the system already exist, take care to consider the following:

a. What will the new equipment receive from?

i. What is the discharge elevation of the upstream equipment?

b. What will it discharge into?

i. What is the inlet elevation of the downstream equipment?

c. What is the centerline distance between the proposed inlet and discharge?

d. Is the proposed route in a straight line or must it turn a corner or change elevation more than once to avoid an existing plant feature?

e. How much width/depth is available to accommodate the new device or equipment?

f. What is the ceiling height?

g. Are there any other layout considerations such as the need to temporarily locate pallets of material, etc. or allow maneuvering room for a fork truck?

Cost

Some consider it taboo to have any upfront discussion with suppliers about budgets, and, yet, there is no denying the role cost plays in the feasibility of every project. Understandably, the justification formula is different from one company to the next. There are initial costs and long-term costs. Some companies weigh more heavily the long-term cost of ownership in their justification calculation, focusing more on reliability, reduced energy consumption and maintenance. Others more heavily weigh the initial investment.

When inquiring about potential solutions, therefore, it is in your interest to have the ability to speak with potential suppliers about these factors so as to obtain from them, as soon as possible, whether a particular approach is likely to gain any traction or whether to consider another approach entirely. Considering how lean companies are and how busy everyone is, it can save precious time and energy to have some of this dialog up front.

History

When replacing existing equipment, the importance of service history cannot be overemphasized. Where reliability has been an issue, understanding the difficulties experienced with existing equipment can provide important clues that enable the incorporation of suitable countermeasures. Simply changing brand names is no guarantee that you will end up with a more reliable, longer-lasting piece of equipment. It is far better to provide details in regard to service history and ask the vendor to explain how the proposed equipment will provide a more satisfactory result.

Summary

The selection and sizing of a conveyor are key considerations to make in successfully meeting production goals. The key factors that should be evaluated when choosing a conveyor are; material, operation, environment, envelope, cost, and history. Taking the time upfront to understand these factors and gather the most accurate data possible related to each component will ultimately make the selection of conveying technology the best for your specific needs and offer the greatest return on investment.