Ground-Level Efficiency: Safer, Cleaner Protein Powder Handling for Baked Goods

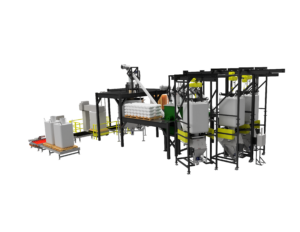

Hapman's flexible screw conveyor system with floor-level dumping, dust collection, and inline screening, the customer was able to enhance operational safety, maintain batch integrity, and support consistent production.

Speed Meets Manufacturing Needs

In today’s fast-paced manufacturing world, adaptability is key. Hapman understands this, which is why we’re excited to highlight our Quick-Ship program for Helix Flexible Screw Conveyors. This innovative solution is…

Efficiency in Batching & Blending: 4 Common Challenges and How to Fix Them

There’s no single solution for any given material handling, batching, or blending application. Significant efficiency improvements require varying degrees of customization to meet your material, processing, and business goals. Asking…

Elevating Material Handling Efficiency with the Helix® Flexible Screw Conveyor

In material handling, reliability and adaptability are key to maintaining smooth operations across industries. Since 1977, Hapman’s Helix® Flexible Screw Conveyor has been a trusted solution for businesses seeking efficient…

3 Reasons Why a “Regular” Flexible Screw Conveyor Might Not Work for You

Manufacturers commonly use flexible screw conveyors because of their low cost, reliability, straightforward operation and simple construction. This equipment is not complicated, but it should not be cookie-cutter either. Poor performance, excessive…

The 6 Key Considerations for Selecting the Right Conveyor System

Selecting a conveyor system for a batch or continuous processing application is not always as straightforward as you may think. In fact, it almost never is. Moving material consistently – at…

How to Keep Your Industrial Business Safe from Dusting

Benjamin Franklin was an author, inventor, politician and one of the Founding Fathers of the United States. He may also have had the uncanny ability to see into the future…

How to Maximize Productivity with the Right Design of Your Flexible Screw Conveyor

Flexible screw conveyors are one of the most common types of conveyors used by manufacturers because of their low cost and simple construction. Although it isn’t a complicated piece of…

Selecting a Conveyor for Effectively Moving Bulk Materials

Although selecting the right conveyor for your bulk material handling application may seem fairly straightforward, oftentimes that is not the case. There are many factors that come into play when…

Maggie Beauchamp, a Hapman sales rep from Gull Material Handling Company, contacted Hapman product specialist, Stephanie Avery, regarding a customer who manufactures premium bakery ingredients including icings, fruit fillings, crème…

Moving Material through a Process: A Guide to Selecting the Right Conveyor

Summary The proper selection and sizing of a conveyor is critical to successfully meeting production goals. The key factors that should be evaluated when choosing a conveyor are; material, operation,…

Helix® Flexible Screw Conveyor Feeds Innovative Form-Fill-Seal Packaging Solution

Based in Grand Rapids, Michigan, IMS Group USA offers bulk solids packaging solutions for the food, pharmaceutical, resin, chemical and other industrial markets. In addition to form, fill and seal…

How Industry Expertise Ensures Correct Flexible Screw Conveyor Selection and Process Uptime

Introduction Most if not all manufacturing operations that deal with bulk materials will agree that downtime and loss of production are at the top of their list of process concerns.…

Planning for expansion is a critical step in a company’s growth plans. Especially when evaluating process improvements and new equipment purchases that will support sustained growth and ensure a maximum…

How to Get the Most Out of Your Flexible Screw Conveyor

Increasing Conveyor Performance and Efficiency Due to their relatively low cost and simple construction, flexible screw conveyors are one of the most common types of conveyors used by manufacturers. The…

Download PDF A4 BUSINESS BENEFITS REALIZED Eliminated dusting – Reduced equipment maintenance issues Potential revenue from waste Additional recycling opportunities Reduced noise levels – created a better working environment for…

Moving Material Through a Process

CHALLENGE Selecting a conveyor for a bulk material handling application is not always as straight forward as one might think. Moving material consistently, at a rate that is inline with…