Choosing a Pneumatic Conveying System: Pressure or Vacuum

Because they are efficient and inherently dust-tight, pneumatic conveying systems provide the most practical method for moving large quantities of dry materials, whether powdered, granulated, or pelletized. Pneumatic conveyor systems, which use an air stream to move materials through horizontal and/or vertical piping, come in two forms: pressure or vacuum.

The Differences and Similarities in Pneumatic Conveyors

Pneumatic conveyors can utilize either a pressure system that introduces compressed air at the system inlet in order to push the material through the piping or a vacuum at the delivery end in order to pull the material through the piping. Pressure and vacuum systems can be used for dense (high pressure/ low velocity) or dilute (low pressure/high velocity) phase operation.

Dense phase conveying systems have a low air-to-material ratio. Velocities are below the saltation level, the critical velocity at which particles fall from suspension in the pipe. Dense phase systems, therefore, move the material through the piping in batches, with discrete dunes or plugs of material separated by pockets of air. Valving systems can be adjusted to reduce the air pockets.

Dillute phase conveying systems have a high air-tomaterial ratio. In this type of system, the material is most often fluidized, or suspended in the air flow, and moves at relatively high velocities depending on the particle size and density. Dilute phase systems usually deliver the material continuously. Material is constantly supplied at the pickup point and is conveyed to the receiver without interruption.

Pressure Systems

The basic components of a pressure system are a rotary air lock feeder valve, a high pressure air compressor system or a low-pressure positive displacement blower or fan to serve as the power source. A pressure vessel, the conveying line, and the receiver make-up the balance of the system. Systems using high-pressure compressed air, operate with pressures above 15 psig, usually with a beginning pressure of about 45 psig and an ending pressure near atmospheric pressure. Low-pressure displacement blowers or fans supply a beginning pressure below 15 psig and an ending pressure near atmospheric pressure.

The basic components of a pressure system are a rotary air lock feeder valve, a high pressure air compressor system or a low-pressure positive displacement blower or fan to serve as the power source. A pressure vessel, the conveying line, and the receiver make-up the balance of the system. Systems using high-pressure compressed air, operate with pressures above 15 psig, usually with a beginning pressure of about 45 psig and an ending pressure near atmospheric pressure. Low-pressure displacement blowers or fans supply a beginning pressure below 15 psig and an ending pressure near atmospheric pressure.

First, the materials is charged into the pressure vessel through the rotary air lock. Once the pressure vessel is filled, the inlet and vent valves close and seal, and highpressure air is gradually introduced into the pressure vessel. The high-pressure air conveys the material to the receiver, where the air and the material are separated by a filter or other system. Valves and sensors control the air pressures and velocities. When the predetermined low pressure setting is reached at the end of the conveying cycle, the air supply is turned off and the residual air volume purges the pressure vessel and the conveying line.

Pressure pneumatic conveying systems are generally preferable when transporting heavier materials longer distances. Pressure pneumatic conveyors can be fairly costly, however, since they require special equipment, like a rotary valve to introduce material into the air stream at the inlet and extra components to remove the air at the discharge end through a vent system.

Vacuum Systems

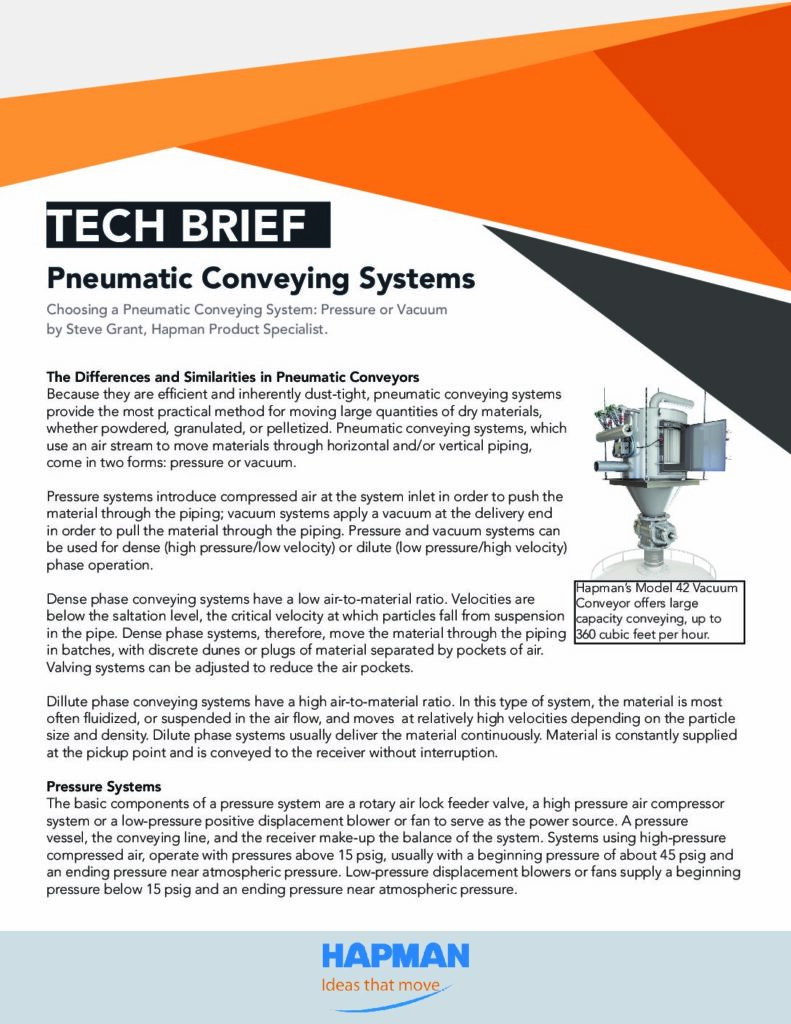

The basic components of a vacuum conveyor system are the pick-up nozzle, the conveying line, the receiver, and the vacuum generator, which is the power source. The vacuum generator creates the required negative pressure to pull the material through the conveying line and into the receiver. A number of devices, including a regenerative blower, a compressed air driven eductor (Venturi) unit, a plant central vacuum using liquid ring vacuum pumps or low-pressure blowers, or a positive displacement vacuum pump, can serve as the vacuum generator. The maximum negative pressure generated and the overall capability of the system, as well as the system efficiency and general operating characteristics, are determined by the type of vacuum generator used.

The air flow created by the vacuum generator moves the material through the conveying piping and into the receiver. There, gravity causes the material to drop into the receiver hopper. Internal filters separate the material from the air to remove any dust and protect the vacuum generator. Delivery of the material from the receiver to its final destination (e.g., process vessels or a packaging line) may be accomplished using a number of methods dependent on application suitability, including a dumpgate simple slide valves, pneumatically operated dump gates, or air lock rotary valves.

Vacuum conveying systems are usually preferred for transporting materials that may tend to pack or plug in a pressure system. They are also a good choice when space is at a premium; for example, attaching a pressure system rotary valve in the limited space below a hopper rail car may be impractical. However, vacuum conveyors are not a good option if you need to transport materials long distances. Because they operate with pressures at or below atmospheric pressure (14.7 psig), vacuum conveyors are limited to a maximum horizontal distance of 50 feet and a maximum horizontal distance of 200 feet. The effective horizontal distance is also reduced by vertical distances and piping bends.

Which Pneumatic Conveyor Best Suits Your Needs?

You will want to consult with one or more pneumatic conveying system specialists before making your decision. However, you should prepare for your discussion by answering the following questions:

- What kind of material is being transported through the pneumatic conveyor? Is material or piping degradation a concern?

- What is the purpose of transferring your materials in a pneumatic conveying system? Do you simply want to move material? Do you want to transfer more material than your current system can handle? Are you more concerned with reliability and efficiency, or gentleness of transport?

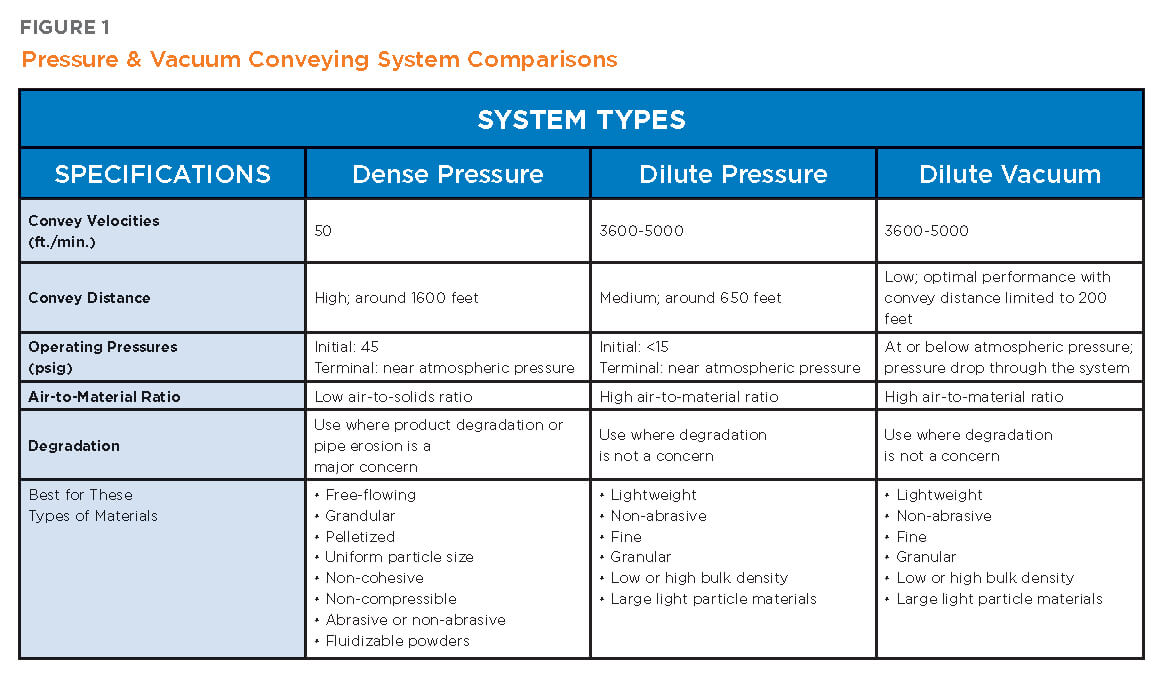

To answer these questions, you need to consider a number of material handling characteristics, including conveyability, optimum air-to-material ratios, buildup tendencies, flowability, and degradation. Figure 1 provides some guidelines to assist you in choosing the right system for the material you need to convey.

Pneumatic Conveying Systems Summary

Pneumatic conveying systems, whether pressure or vacuum, are an excellent choice for providing efficient and dust-free conveying. And while pressure systems are preferred for conveying heavier materials longer distances, vacuum systems are the conveyor of choice for materials that have a tendency to pack or where physical space within the plant is limited. Because of the seemingly limitless variability in system requirements and diverse material bulk densities, designing an optimized system must first begin with identifying these elements with a qualified conveying expert. Taking into account the physical needs of the plant environment, the availability of plant air, and characteristics of the materials being conveyed will ensure that your pneumatic conveying system is the best, most efficient and economical choice for your current and future needs.