Regenerative Blower-Driven Vacuum Conveyors Fill Niche for Efficient, Small-Footprint Pneumatic Conveying

By Steve Grant, Product Specialist

Pneumatic conveying systems are frequently an excellent choice for moving large quantities of powdered, granulated or pelletized material. And among the many different approaches to pneumatic conveying, regenerative blower-driven vacuum systems can provide ideal cost effciencies, compactness and simplicity where vacuum requirements and transfer distances are modest.

Many other types of pneumatic conveying systems like pressure-driven systems are designed for moving heavier materials over longer distances; they require fairly robust pressure, large capital equipment investments, more operating energy and higher maintenance costs. Downscaling this kind of pressure-driven technology to meet the needs of smaller-volume, shorter-distance transfer isn’t always a practical or economical approach. Fortunately, regenerative blower-driven vacuum systems like those produced by Hapman give processors the right combination of design and operating characteristics for excellent economics in lighter-duty situations.

Operating principles of vacuum conveying systems

Vacuum conveyors are relatively simple systems that include a pick-up inlet, a conveying tubing line, a receiver and a vacuum generator, which is the power source. The vacuum generator creates the required negative pressure to pull the material through the conveying line and into the receiver. Internal filters separate the material from the air to remove any dust and protect the vacuum generator. A number of different gating systems may be used for removal of product from the receiver, including simple sliding valves, pneumatically-operated dump gates or air lock rotary valves.

Power source options for vacuum systems include regenerative blowers, compressed air driven eductor (venturi) units, plant central vacuum using liquid ring vacuum pumps or low-pressure blowers or positive displacement vacuum pumps. With the exception of regenerative blowers, all of these vacuum power sources are external to the conveying equipment itself.

Vacuum systems are preferred for transporting materials that tend to pack or plug in a pressure system. And they are excellent choices where space is at a premium. With many lightweight materials, their conveying velocities can be quite high, between 3,600 and 5,000 feet per minute. One notable limitation is reach; they’re not typically used for conveying distances above 200 feet, or where vertical distances are above about 50 feet.

Integral vacuum generator

Unlike almost any other pneumatic conveying technology, regenerative blower equipped conveying systems like Hapman’s are unique in that the vacuum generator is integral to the system; no external plant air or vacuum is required.

The regenerative blowers that power these systems are very simple and reliable. They have few parts, just an electric motor with sealed bearings, an impeller and a housing with a cover. There are no other moving parts or wear parts that require lubrication of maintenance.

Inner workings of a regenerative blower

Regenerative blowers work on a vortex air flow principle. Air is effectively moved between vanes as a single-stage impeller rotates in a casing. The spinning impeller and air flow create a vortex flow pattern which boosts velocity incrementally as the air moves from vane to vane inside the housing. The flow of air on the output side is very steady and smooth. Product lines like Hapman’s include blowers from 1.5 to 15 hp, which can supply suffcient vacuum for material conveying capacities up to 18,000 lb./hour.

Advantages of Stand-Alone Regenerative Blower Vacuum Conveying Systems

Lower initial costs – Regenerative blower vacuum conveying systems are self-contained, requiring only an electric power hookup. There’s no requirement for air or vacuum supply runs, or for internal studies of available capacity utilization. For facilities without plant air or vacuum supply already in place, operators avoid the expense of planning, installing and maintaining these external vacuum power systems.

Lower operating costs – Compared to externallypowered pneumatic conveying systems, onboard regenerative blower systems offer considerably higher energy effciency, typically twice that of conventional air compressor-driven systems. Maintenance costs are also much lower, especially when compared to external air compressors or positive displacement (PD) blowers, where ongoing maintenance items include lubrication and replacement or maintenance of filters, belts, regulators, coolers, muffers and plant air lines.

No competition for plant air or vacuum – These self-contained systems place no additional demand on plant air systems. It’s an advantage in terms of overall capacity planning and swing capacity availability for other users in the facility during peak demand periods.

Easy to install – Regenerative blower vacuum systems weigh less and take up less space than other pneumatic conveying systems. They’re easier to transport into manufacturing environments, and they’re simpler to install.

Easy to clean – For routine filter cleaning, regenerative blower systems like Hapman’s are designed for easy filter element access without tools. Where there’s a need for overall system cleaning, regenerative blower systems are available with provisions for central unit and tubing washdowns.

Oil-free air – Regenerative blowers don’t require internal lubrication, so they produce oil-free air.

Low noise – Noise levels for these systems are very low compared to other air or vacuum supply systems.

Comparisons to Other Air/Vacuum Supply Technologies

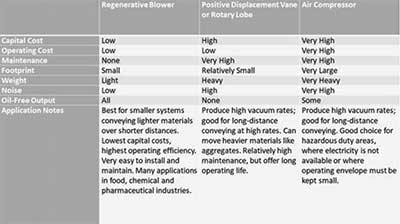

Table 1 provides a useful comparison of regenerative systems to two alternatives, positive displacement and air compressor technologies, that are sometimes used in similar applications.

Case Studies: Real-World Solutions to Production Challenges

Automating Material Handling System Improves Worker Safety, Economics and Production Rates

Werner G. Smith, an Ohio-based chemical manufacturer, was awarded a long-term contract for a new customer to blend a granular powder with an aqueous chemical solution. Werner was able to dedicate a large reactor to the contract manufacturing process, but the building housing the reactor presented serious logistics issues. There was no loading dock, and to get the operation up and running quickly, Werner initially relied on a team of five employees to manually carry 55 lb. bags of material into the building and up one story where an operator would manually dump material into the reactor. In the course of a week’s production the team had to handle over 800 55 lb. bags of material.

Said Jennifer Bugbee, Vice President of Operations at Werner G. Smith, “This was an enormous waste of time and manpower, and we needed to streamline the process, reduce powder hazards and reduce strain on the workforce.” Through a local industrial equipment supplier, Werner connected with Hapman.

Hapman designed a material handling system that included a Loss-in-Weight Bulk Bag Unloader that feeds a Hapman Vacuum Conveying System that delivers material to process. The vacuum conveyor system includes an integral regenerative vacuum blower, integral filtration, a reverse pulse filter cleaning mechanism and automated batch controls.

The returns for Werner G. Smith were almost immediate. Production time improved by several hours per batch, and facility housekeeping improved dramatically. The system also eliminated the need for a third-party vendor to break down and repackage material into 55 lb. bags so Werner employees could manually handle them. The five employees were assigned to duties more directly related to production.

Vacuum Conveying System Eliminates Cross-Contamination for Pharmaceutical Company

A major pharmaceutical company came to Hapman with a need for a vacuum conveyor system to take their finished product from a dryer and discharge it into a mobile bulk material handling system, which was scale mounted for precision metering and batching. The challenge was that it needed to incorporate an efficient cleaning system to eliminate any possibility of cross-contamination with product change overs.

Hapman engineered a pneumatic vacuum conveying system with individually controlled spray wash ports placed throughout the interior of this material handling conveyor. This self-contained design allowed the customer the ability to reliably clean and sanitize the conveyor’s interior without the need for time-consuming external procedures. Further time saving enhancements included a side access door for quick filter cartridge change outs, and a cleanin- place rotary valve which allowed disassembly, cleaning and reassembly within minutes. The entire sanitary finish assembly was 304 stainless steel with sealed motors and controls rated for explosive atmosphere and wash down applications.

The completed system delivered on all design goals. Effciency and processing rates were subsequently increased.

Conclusion: The Ideal Choice for Modest Production Requirements

Regenerative blower-driven vacuum conveying systems certainly aren’t for every application. They aren’t a viable alternative to the more powerful systems needed for longer transfer distances and heavier materials. But as described here, they deliver an outstanding suite of advantages for smaller, shorter-run conveying systems that operate at lower vacuum or air consumption rates. Their effciency, simplicity of operation, small footprint and low maintenance requirements mean they can deliver a unique combination of economics and practicality.

Advantages of Pneumatic Conveying

Whether pressure- or vacuum-powered, pneumatic conveying systems offer processors many advantages, including:

- Simple; essentially tubing, receiver and vacuum source

- Fully enclosed, no dusting, contamination, ignition spark generation

- No large, heavy conveyors with numerous wear parts and maintenance

- Good-to-excellent energy-effciency

- Can run horizontally and vertically

- Quiet