Revolutionizing Battery Manufacturing and Recycling Through Expert Material Handling

At Hapman, we are at the forefront of innovation in battery manufacturing and recycling, with an unwavering focus on efficient material handling. As the world seeks cleaner and more sustainable energy solutions, we understand that the key to success lies in optimizing the handling of essential materials within the battery industry.

Mastering the Art of Material Handling

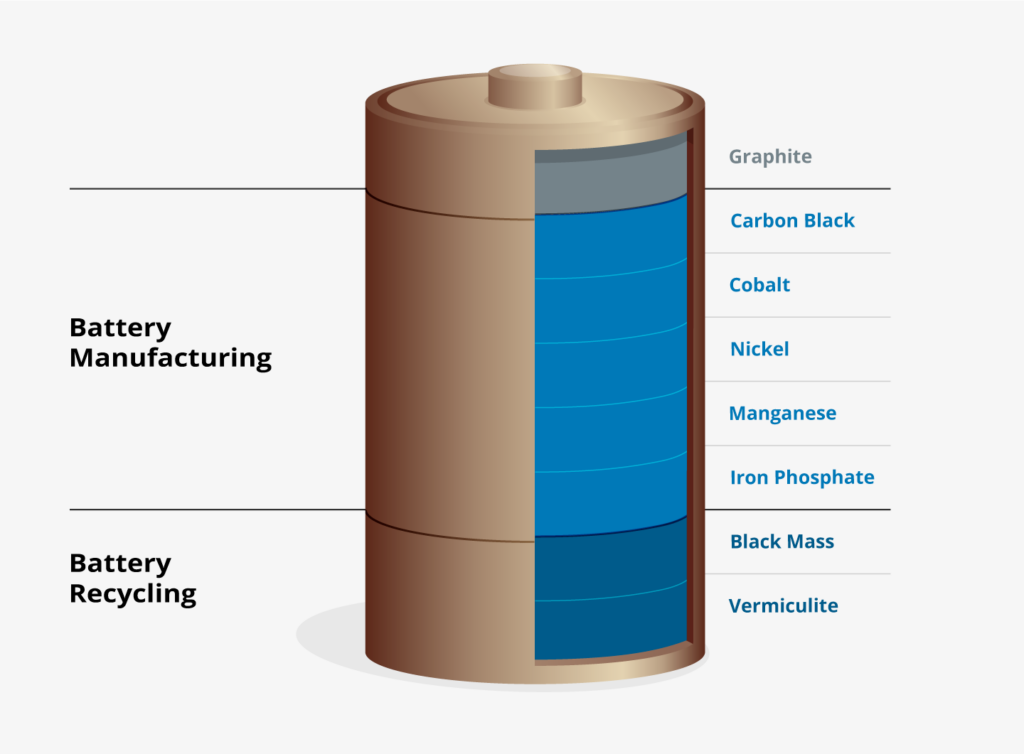

Material handling is not just a process; it’s an art. It’s the art of precision, efficiency, and sustainability. In battery manufacturing and recycling, it is the art of ensuring that materials like Graphite, Carbon Black, Cobalt, Nickel, Manganese, and Black Mass are handled with the utmost care, precision, and expertise.

Carbon Black: The Challenge and Opportunity

Carbon Black is a versatile and critical component in various industries including battery production. However, it presents a unique set of challenges due to its physical properties and handling requirements. Carbon Black is a finely divided carbonaceous powder with a high surface area, making it highly prone to dusting and creating potential safety hazards. Its fine particle size also makes it challenging to control during transportation, storage, and processing. Ensuring uniform dispersion and precise incorporation into battery materials, while minimizing waste and ensuring worker safety, requires specialized equipment and handling expertise. With decades of industry experience and a proven track record, we’ve established ourselves as the go-to experts in Carbon Black handling solutions. We understand the unique challenges posed by Carbon Black, and our innovative solutions are designed to address them with precision and reliability.

Explore additional battery production and recycling opportunities through

our KMC Global family of companies.