Efficient Material Handling with Vacuum Conveyors

In bulk material handling, efficiency and versatility are paramount. Vacuum Conveyors are designed to optimize material movement across various sectors, ensuring cost-effective and reliable operations. Key Features of Hapman Vacuum…

Efficiency in Batching & Blending: 4 Common Challenges and How to Fix Them

There’s no single solution for any given material handling, batching, or blending application. Significant efficiency improvements require varying degrees of customization to meet your material, processing, and business goals. Asking…

Transforming Pharmaceutical Efficiency with Innovative Conveyor Technology

PROBLEM: A leading pharmaceutical company approached Hapman for help in designing a vacuum conveyor system tailored to their needs. They required a system to transfer their finished product from a…

The 6 Key Considerations for Selecting the Right Conveyor System

Selecting a conveyor system for a batch or continuous processing application is not always as straightforward as you may think. In fact, it almost never is. Moving material consistently – at…

Selecting a Conveyor for Effectively Moving Bulk Materials

Although selecting the right conveyor for your bulk material handling application may seem fairly straightforward, oftentimes that is not the case. There are many factors that come into play when…

Moving Material through a Process: A Guide to Selecting the Right Conveyor

Summary The proper selection and sizing of a conveyor is critical to successfully meeting production goals. The key factors that should be evaluated when choosing a conveyor are; material, operation,…

Choosing a Pneumatic Conveying System: Pressure or Vacuum Because they are efficient and inherently dust-tight, pneumatic conveying systems provide the most practical method for moving large quantities of dry materials,…

Vacuum Conveying System Eliminates Cross-Contamination for Pharmaceutical Company

CHALLENGE A major pharmaceutical company came to Hapman for assistance in providing them with a vacuum conveyor system to meet their specific requirements. It was to take their finished product…

Download PDF A4 CHALLENGE A processor must expand its capacity and add new lines in half the time normally required for such a project. The material being conveyed is a…

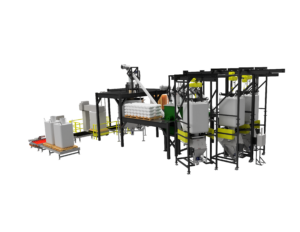

Bulk Bag Unloader and Vacuum Conveyor System Automates Material Handling and Adds Cost Savings

CUSTOMER Werner G. Smith INDUSTRY Chemical CHALLENGE Werner G. Smith, Inc. was awarded a long-term contract from a new customer which required the blending of a granular powder with an…

Moving Material Through a Process

CHALLENGE Selecting a conveyor for a bulk material handling application is not always as straight forward as one might think. Moving material consistently, at a rate that is inline with…