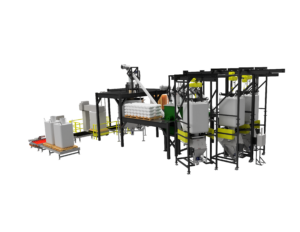

Efficiency in Batching & Blending: 4 Common Challenges and How to Fix Them

There’s no single solution for any given material handling, batching, or blending application. Significant efficiency improvements require varying degrees of customization to meet your material, processing, and business goals. Asking…

The 6 Key Considerations for Selecting the Right Conveyor System

Selecting a conveyor system for a batch or continuous processing application is not always as straightforward as you may think. In fact, it almost never is. Moving material consistently – at…

5 Reasons to Avoid Round-Link Chains in Tubular Drag Conveyors

Tubular drag conveying is a common method of moving loose bulk materials between processes in industrial plants. Chain-type tubular drag conveyors fall into two basic categories: those that use round-link chains and…

How to Keep Your Industrial Business Safe from Dusting

Benjamin Franklin was an author, inventor, politician and one of the Founding Fathers of the United States. He may also have had the uncanny ability to see into the future…

Selecting a Conveyor for Effectively Moving Bulk Materials

Although selecting the right conveyor for your bulk material handling application may seem fairly straightforward, oftentimes that is not the case. There are many factors that come into play when…

How the “Bend But Don’t Break” Principle Applies to Tubular Drag Conveyors

If you’re a sports fan, you know that the term “bend but not break” refers to a football defense that gives up yardage but doesn’t allow the opponent into the…

Hapman partners with several major Wastewater Treatment facility developers meeting critical requirements around dosing treatment materials and sludge handling. Hapman Bulk Bag Handling, Helix flexible screws, and feeders manage dosing…

Moving Material through a Process: A Guide to Selecting the Right Conveyor

Summary The proper selection and sizing of a conveyor is critical to successfully meeting production goals. The key factors that should be evaluated when choosing a conveyor are; material, operation,…

Top Equipment Design Considerations for Handling Bulk Chemical Powders

“Successful conveying and handling of chemical powders requires much more input than understanding a material’s properties, the desired convey rate and distance. Today’s manufacturers are faced with tighter margins, leaner…

Issues of Unloading Ammonium Nitrate Prill are Eliminated with Tubular Drag Conveyor System

“Hapman and their local representative worked very hard to ensure the successful completion of our client’s project,” stated O’Connor. “Their efforts helped identify and implement the optimum solution in order…

The Case for Engineered Chains Over Round-Link Chains

Both varieties of chain-type tubular drag conveyors often compete for the same work. Here’s why they shouldn’t. The concept of tubular drag conveying is a common consideration among industries needing…

Key Factors of Material Handling Equipment Design and Selection

Considerations When Handling Dry Ingredients INTRODUCTION Successful conveying and handling of dry ingredients requires much more input than understanding a material’s properties, the desired convey rate and distance. Today’s manufacturers…

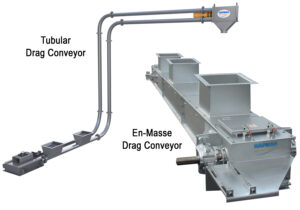

Understanding the Functional Differences Between Drag Conveyor and En-Masse Drag Conveyor Chain conveyors whether known as Drags, Scraper, Paddle, or En-Masse all start out with a continuous chain and fixed…

Tubular Drag Conveying – A Cost-Effective, Energy-Saving Alternative to Pneumatic Conveying

Pneumatic conveying is often considered the standard solution for transferring materials in bulk solids plants. In many applications, however, a type of mechanical conveying — tubular drag conveying — can…

The Evaluation of Tubular Drag Conveyor Types

The Tubular drag conveyor has become the system of choice for many manufacturers who process bulk materials because of the conveyor’s layout flexibility, many flight and chain options that prevent…

CHALLENGE A fully operational research laboratory needed a better way for technicians to remove and dispose of more than 1,200 pounds of soiled animal bedding per day. CUSTOMER Uniformed Services…

CHALLENGE The facility, which manages over 55,000 rodent cages, needed a more reliable and cost effective way to dispose of waste bedding, as well as mitigate allergen exposure, and reduce…

Biotech Lab Handling Dirty Mice Bedding From Cages with Cleaning Disposal System

CHALLENGE A biotech lab needed an easy and dependable method to handle dirty animal bedding from cages. SOLUTION A Hapman tubular drag conveyor with a specialized dump hopper. The cages…

CHALLENGE A mining operation located in the mountains of Chile required an equipment method to handle and convey ammonium nitrate (NH4NO3) without degradation, 50 feet vertically, into a silo. Their…

Innovative Conveying Solutions: Ensuring Safety, Protecting Materials, and Enhancing Efficiency

CHALLENGE Engineering conveying systems for today’s processors requires far more than just moving product from point A to point B. Engineers must also consider plant and worker safety through assessing…