Helix® Flexible Screw Conveyor Feeds Innovative Form-Fill-Seal Packaging Solution

Based in Grand Rapids, Michigan, IMS Group USA offers bulk solids packaging solutions for the food, pharmaceutical, resin, chemical and other industrial markets. In addition to form, fill and seal…

Issues of Unloading Ammonium Nitrate Prill are Eliminated with Tubular Drag Conveyor System

“Hapman and their local representative worked very hard to ensure the successful completion of our client’s project,” stated O’Connor. “Their efforts helped identify and implement the optimum solution in order…

Planning for expansion is a critical step in a company’s growth plans. Especially when evaluating process improvements and new equipment purchases that will support sustained growth and ensure a maximum…

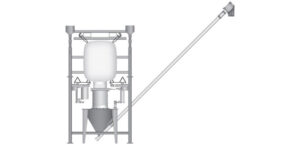

Bulk Bag Filler – Plastics Manufacturer Uses Bulk Bag Filler FIBC System

CHALLENGE A plastics manufacturer needed a bulk bag filler that could be adjusted to fill a variety of large bag sizes (tall as 72 inches). In addition, the customer required…

Vacuum Conveying System Eliminates Cross-Contamination for Pharmaceutical Company

CHALLENGE A major pharmaceutical company came to Hapman for assistance in providing them with a vacuum conveyor system to meet their specific requirements. It was to take their finished product…

CHALLENGE Deliver measured amounts of four powdered ingredients, received in bulk bags to slurry tanks. Some materials are hygroscopic, flow poorly in humid environments and may contain small agglomerations. Whereas…

Mixing Solutions and Slurries – Effectively, Economically, and Safely Mixing Diatomaceous Earth

EP Minerals, located in Reno, Nevada, is a major producer of diatomaceous earth, cellulose and perlite filter aids, coatings, absorbents, and soil additives. The company enlisted Hapman to help develop…

CHALLENGE Manually shoveling sand to fill cope and drag boxes (casting flask) for sand casting is a physically demanding process for mold makers, who on average shovel 20 tons of…

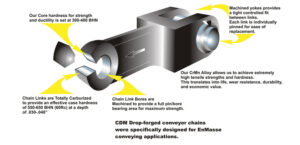

Drag Chain Conveying System Supports Refinery Filter Cake Recycle and Reuse

CHALLENGE A large oil company sought to expand refinery operations at one of their global locations. The expansion required an effective way to handle the filter cake at a new…

Hapman Maintains EPA Standards by Meter Feeding Enviroblend into a Dust Collection System

CHALLENGE EPA standards required this company to feed Enviroblend® into their dust collection system at a precisely controlled rate of 30 pounds per hour so the emissions would be at…

Download PDF A4 CHALLENGE A processor must expand its capacity and add new lines in half the time normally required for such a project. The material being conveyed is a…

Overcoming the Challenges of Handling Salt in Bulk – The Moisture Absorbing Nature of Salt

CHALLENGE An Italian food processor added a new pasta line to meet growing demand for small batch, premium pasta. The granulated salt used for this process came in 2,000 lb…

Bulk Bag Unloader and Vacuum Conveyor System Automates Material Handling and Adds Cost Savings

CUSTOMER Werner G. Smith INDUSTRY Chemical CHALLENGE Werner G. Smith, Inc. was awarded a long-term contract from a new customer which required the blending of a granular powder with an…

CHALLENGE Harry Harman, P.E. of Baxter & Woodman, consulting Engineers, received a call from an official with the Village of Gilberts in the State of Illinois. The call was a…

CHALLENGE A fully operational research laboratory needed a better way for technicians to remove and dispose of more than 1,200 pounds of soiled animal bedding per day. CUSTOMER Uniformed Services…

CHALLENGE The facility, which manages over 55,000 rodent cages, needed a more reliable and cost effective way to dispose of waste bedding, as well as mitigate allergen exposure, and reduce…

Biotech Lab Handling Dirty Mice Bedding From Cages with Cleaning Disposal System

CHALLENGE A biotech lab needed an easy and dependable method to handle dirty animal bedding from cages. SOLUTION A Hapman tubular drag conveyor with a specialized dump hopper. The cages…

CHALLENGE A mining operation located in the mountains of Chile required an equipment method to handle and convey ammonium nitrate (NH4NO3) without degradation, 50 feet vertically, into a silo. Their…

CHALLENGE A major tire manufacturer needed to fit a material handling conveyor into a tight space, move the material (carbon black) from inlets and discharge it at two locations. In…

CHALLENGE A fast growing, finished product food processor was using aeromechanical conveyors to convey product in their production operations for processing and prepackaging. Unfortunately, the aeromechanical conveyors caused serious problems…

Download PDF A4 CHALLENGE A pelletized fuel manufactuer was spending time and effort maintaining a conveyor that also created fines and dust. CUSTOMER Fiber By-Products Corporation INDUSTRY Pelletized Fuel Manufacturer…

Stillwater Mining Improves Smelting Efficiency and Yield, Eliminates Dust with Tubular Drag Conveyor

CHALLENGE Stillwater Mining was challenged with maintaining constant temperatures in a smelting furnace to ensure efficient extraction. Also, to create a safe, environmentally friendly process for dumping bulk bags of…

CHALLENGE More than 150 bags of bedding are required to support the cage changing process performed weekly. When plans were in place to construct a new multi-story vivarium, Laboratory Animal…

Human Health Benefits, Operational Efficiencies, Increased Productivity, Cost Improvements

Case Study: Human Health Benefits, Operational Efficiencies, Increased Productivity, Cost Improvements CHALLENGE GlaxoSmithKline faced a waste bedding management challenge involving both laboratory animal allergies and ergonomic related employee injuries. CUSTOMER…

CHALLENGEOne of the nation’s largest producers of snack foods required a way to quickly clean the conveyor in between batches. It also required the ability to move the conveyor from…

Sweets Manufacturer Batching from Standard and Bulk Bags

Challenge A major manufacturer of sweets required a highly versatile system to convey and accurately weigh batches for mixing and discharge into a hopper before final processing into their calcium…

CHALLENGE A chemical company had to periodically charge their holding hoppers with ground limestone. Due to the number of hoppers and their infrequent need for charging they did not feel…

Download PDF A4 BUSINESS BENEFITS REALIZED Eliminated dusting – Reduced equipment maintenance issues Potential revenue from waste Additional recycling opportunities Reduced noise levels – created a better working environment for…

Helix® is the Top Choice for Specialty Dry Bulk Food Company

CHALLENGE Guixens Food Group, located in Tampa, Fla., needed a single conveyor for their new facility that could handle material bulk densities ranging from ultra-fine corn flour to fragile dry…

Issues of Unloading Ammonium Nitrate Prill are Eliminated with Tubular Drag Conveyor System

CHALLENGE Help transition a facility from manufacturing plant to distribution hub. Design and build a safe, automated way to unload bulk material from railcars. CUSTOMER Dyno Nobel INDUSTRY Mining The…